- Jun 5, 2016

- 5,543

- Boat Info

- 410 Sundancer

2001

12" Axiom and 9" Axiom+ MFD

- Engines

- Cat 3126 V-Drives

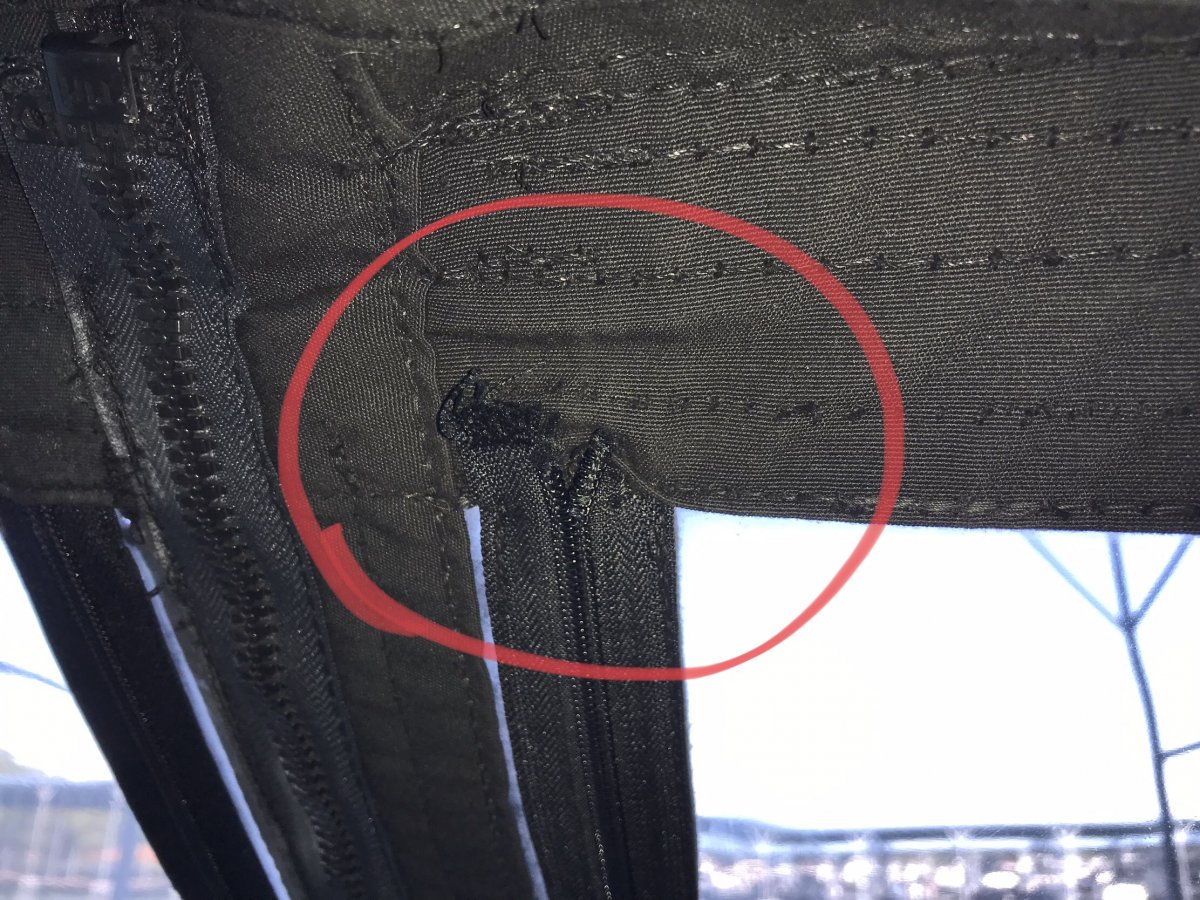

Front curtains have "smilies" cut in and a light guage YYK coil zipper sewn in. The zipper has come apart at one end. Whats the best option to repair? Looking for a DIY solution till the season is over.

Edit: The loops have been damaged as I tried to put the pull back on, and the fabric has frayed ends...

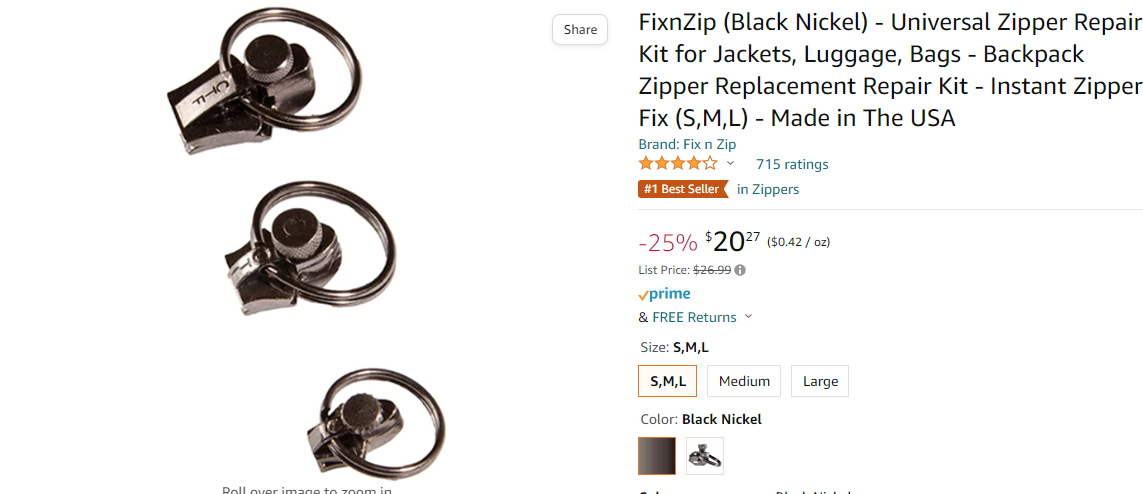

I found these to try as I have some other zippers that need attention. Evidently mine are Riri, and no longer suported in the US and not compatible with YYK. Of course they arent!

Edit: The loops have been damaged as I tried to put the pull back on, and the fabric has frayed ends...

I found these to try as I have some other zippers that need attention. Evidently mine are Riri, and no longer suported in the US and not compatible with YYK. Of course they arent!