techmitch

Well-Known Member

- May 1, 2008

- 8,323

- Boat Info

- 1999 270 DA

- Engines

- Twin 4.3s W/Alpa I Gen II's

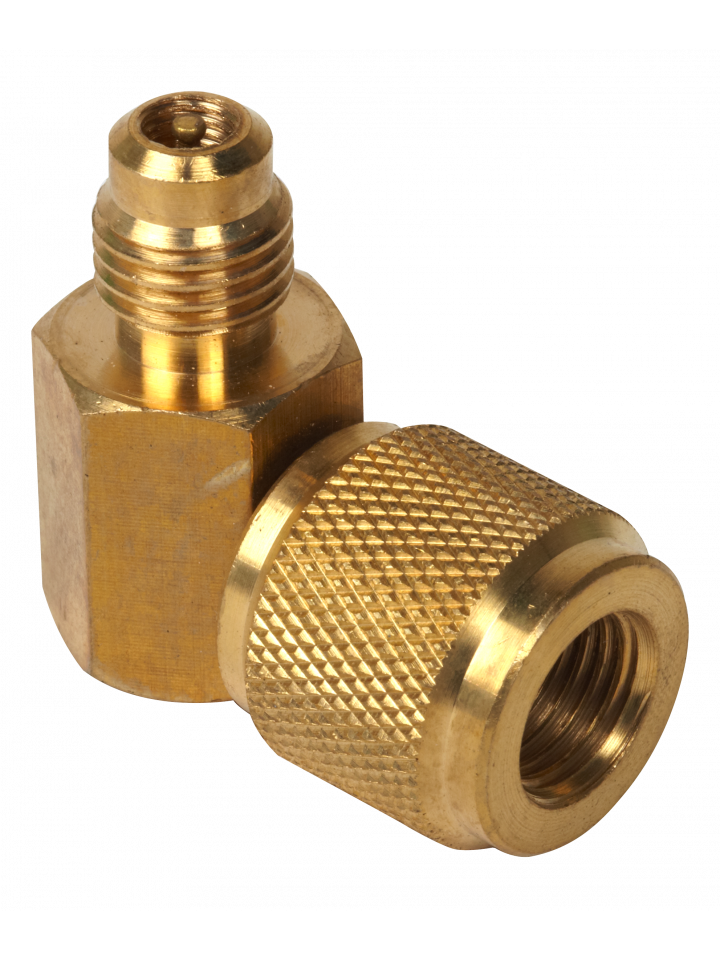

Love mine: https://www.ebay.com/i/382895639345?chn=ps

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

PlayDate, thanks for your insight. I am not beyond thinking I have more than one issue. The fuel pressure gauges were really throwing me off. One day they were reading 38-40 and the next barely 20. I sure wish GM would have put the schrader valve in a more accessible place than halfway under the plenum.

What tool or technique do you use to perform a cylinder balance test without getting knocked across the room? The ECMs are too old to let me do it with a scan tool.

Playdate - l too thought ignition at first, but that doesn't explain the stalling? Fuel pressure was not increasing off idle which should be the case. That told me fuel related.

Please source your 90 degree fitting. I'd really like to set up some permanent fuel flow meters for the pair. Not sure I can trust the adapter hose that comes with the flow gauges long term.I haven't completely ruled out a fuel pressure problem but he needs a reliable setup that matches what we see in the run data. It is a pain to connect to the Schrader valve on that fuel rail which can cause the hose to kink and throw the readings off. I have a 90 degree Schrader fitting that makes it easier to attach a hose. Once we get some reliable numbers testing the pump and the regulator.....that will really help.

Spark plugs pics

https://www.dropbox.com/sh/edbh4zkgric0fcx/AACVeQIVh-0dVOMeUejc0Mjea?dl=0

This was this morning before I did anything.

Yup oil,...nothing short of a rebuild will bring this thing back to life....crappy compression numbers told the story 50 posts ago.

All of the injectors are brand new. I did that a couple of months ago thinking the same thing. And, when I replaced the ones on the starboard engine, that was the fix that took it to top performance. They are aftermarket, but the same ones I used on the Starboard engine. Could I have pinched an o-ring? maybe. could I have cracked an injector plug? not likely but possible. I've lived through all of those mistakes made by me, and other mechanics before me.I believe you are getting closer to the actual problem. That is good news on the fuel pressure. Do you know if any of the injectors have been replaced on the port engine?

All of the injectors are brand new. I did that a couple of months ago thinking the same thing. And, when I replaced the ones on the starboard engine, that was the fix that took it to top performance. They are aftermarket, but the same ones I used on the Starboard engine. Could I have pinched an o-ring? maybe. could I have cracked an injector plug? not likely but possible. I've lived through all of those mistakes made by me, and other mechanics before me.

It's easy enough to pull the rail and check. I'm just running out of plenum gaskets.....