- Aug 20, 2021

- 1,308

- Boat Info

- Started out as MAYBE A DANCER

Became a Dancer - 12/23/21

- Engines

- 450 DA Sundancer running CAT 3126

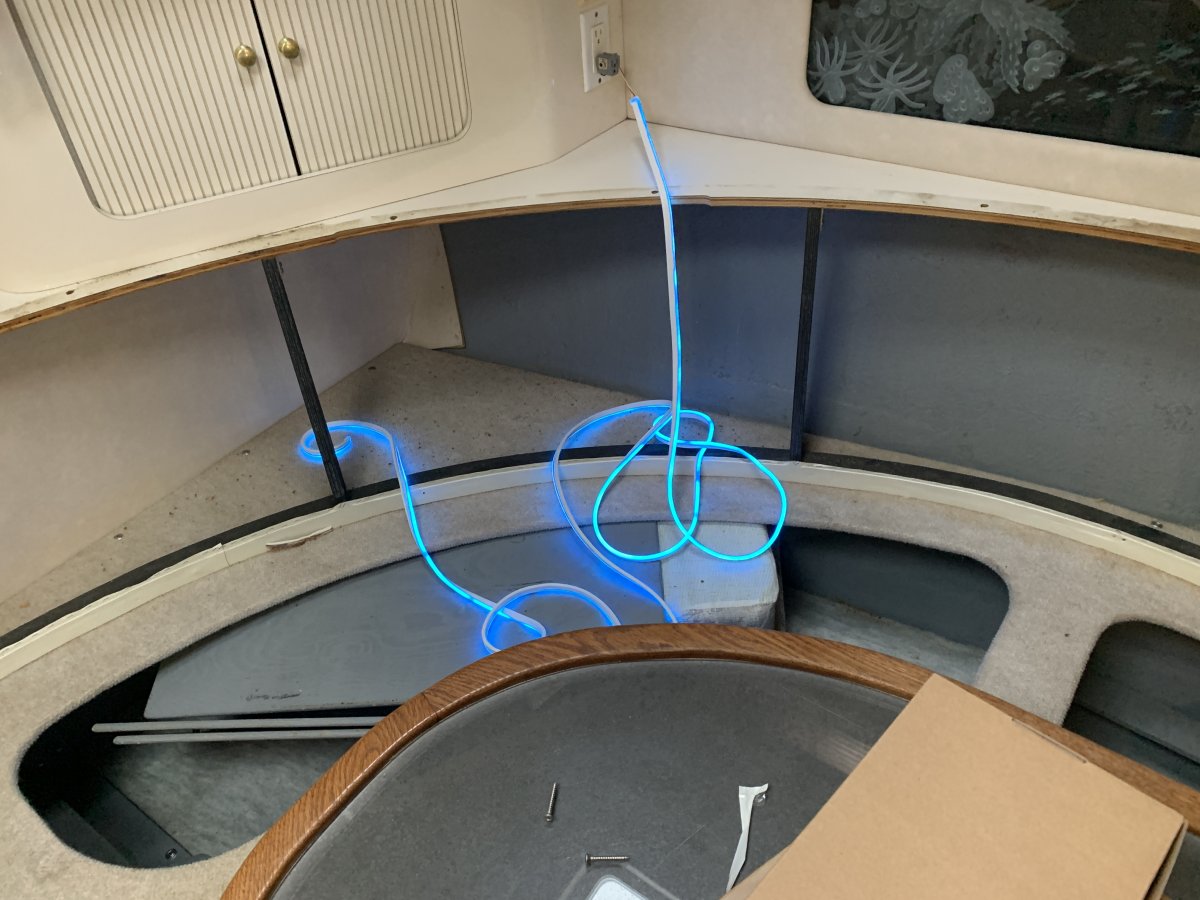

I bought a roll of AQUA BLUE 120v LEDs

Would be a major improvement over the currently displayed URINE YELLOW

I'll give the right hand side a try today, but must be careful not to damage those "aquariums"

Here's my current non-access pics:

Hey, at least I got to vacuum up 26 years of schmutz from behind/below those cushions

PLEASE IGNORE the disgusting, stained carpet.

It's on the list but not before I seal the windshield base and some other more serious items.

BEST !

RWS

Would be a major improvement over the currently displayed URINE YELLOW

I'll give the right hand side a try today, but must be careful not to damage those "aquariums"

Here's my current non-access pics:

Hey, at least I got to vacuum up 26 years of schmutz from behind/below those cushions

PLEASE IGNORE the disgusting, stained carpet.

It's on the list but not before I seal the windshield base and some other more serious items.

BEST !

RWS