I tend to agree there was some skullduggery on the wiring. No way should the Systems Monitor be associated with the run and start circuits.Thanks. In my case I'm replacing a BCGTC with a BCGB and they are connected to the boat very differently. The BCGTC was working, but it had a giant hole in the block where a connecting rod tried to escape. Holding the On switch in the ON position allowed it to run, bypassing the lack of oil pressure. So, there is no issue with the boat as wired. (as purchased - seller said he was using it in the past, and knew nothing about a thrown rod - whole other topic!)

If I knew what the Violet wire's purpose was, that would be helpful. Since the 2 halon wires are direct connected to the 2 Generator wires in the System Monitor, and the Violet one can't can found at the genset, it's a quandary. The other wire goes to the aux oil pressure switch, so it's purpose is clear - it signals the System Monitor of Oil Pressure loss (the primary would shutdown the genset at the same time, so a bit redundant), but why it connects to the Halon system makes no sense.

The BCGB control panel is nearly identical to the BCGTC, but the 5 extra wires in the BCGTC don't correlate to any drawing of each generator. The only difference I see is how the choke solenoid is energized.

The later version of our boat, 380AC, has a genset drawing that looks like the BCGTC terminal block connected to the BCGB style 15 pin connector, but it uses 2 switches, and no Monoplex.

I have have decades of electronics & electrical background, and this has me baffled. Mostly due to a lack of correlation between the boat and the published wiring diagrams.

I think getting into the harness, and tracing wires, may be my only option at this point.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Westerbeke BCGB Remote Connector

- Thread starter John E3

- Start date

John E3

Active Member

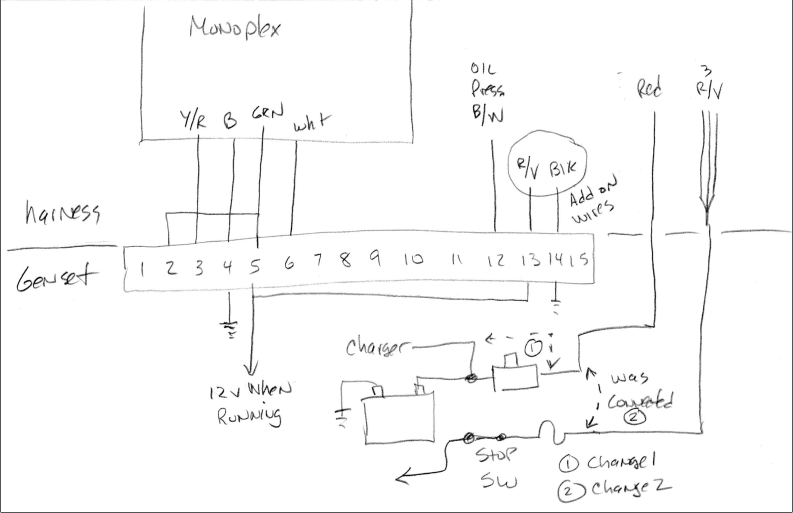

I spent some more quality time with various resources last night, and may be getting closer to the end result. I drew out the wiring I have actually found in my BCGTC generator connections, and found an interesting situation that was not obvious from just the notes. The 3 r/v wires coming off the fuse may in fact be going to 2 of the 'other' r/v wires - Monoplex 12v supply and the hour meter. The 3rd is still a mystery. From other runs in the wiring diagrams, it looks like they use r/v for switched power to -many- devices. Could be a standard?

The monoplex r/v wire thought was derived from the 380AC wiring diagrams and that mysterious "remote bypass" switch, which also shows the violet wire from the Systems Monitor connected to that as well. This suggests this wire is feeding power when the genset is running, and illuminates the 'gen on' indicator, although the monoplex needs 12v in order to start the generator, so that muddies the water. My Monoplex has a r/v wire on the 12v connection.

The r/v wire on the hour meter also seems a bit odd, as the default wiring in the genset control has it in parallel with all the other 'run' devices - fuel solenoid, fuel pump, coil, etc, and they all connect to the Run lead on the terminal board (connected to Monoplex Run), but they should be getting power from this connection, not the jumpered wire on the Hour meter.

I'm starting to think that the genset control has been re-wired by Sea Ray to support the Monoplex. Next step on that is to pull the panel out and trace wires looking for deviation from the westerbeke diagram. I know for sure the fuse connection, and hour meter, is different. And open the harness to trace the wires from the genset to the bulkhead. On the wiring diagram there is a note specifically calling out "splice point" on the violet wire for halon to genset wire. Maybe I will find this hidden in the harness?

The 15pin to terminal board diagram in the 380 manual, with dual MDP switches (on & start/stop), turned out to be -very- helpful. I drew up a diagram of it in the same layout as my 370 diagram and was able to correlate every wire by name and function, so now I have the Monoplex to 15pin wiring confirmed. But it does not account for the 3 r/v wires to the fuse, or the wire pair on the hour meter.

Baby steps....

Drawings so far attached.

The monoplex r/v wire thought was derived from the 380AC wiring diagrams and that mysterious "remote bypass" switch, which also shows the violet wire from the Systems Monitor connected to that as well. This suggests this wire is feeding power when the genset is running, and illuminates the 'gen on' indicator, although the monoplex needs 12v in order to start the generator, so that muddies the water. My Monoplex has a r/v wire on the 12v connection.

The r/v wire on the hour meter also seems a bit odd, as the default wiring in the genset control has it in parallel with all the other 'run' devices - fuel solenoid, fuel pump, coil, etc, and they all connect to the Run lead on the terminal board (connected to Monoplex Run), but they should be getting power from this connection, not the jumpered wire on the Hour meter.

I'm starting to think that the genset control has been re-wired by Sea Ray to support the Monoplex. Next step on that is to pull the panel out and trace wires looking for deviation from the westerbeke diagram. I know for sure the fuse connection, and hour meter, is different. And open the harness to trace the wires from the genset to the bulkhead. On the wiring diagram there is a note specifically calling out "splice point" on the violet wire for halon to genset wire. Maybe I will find this hidden in the harness?

The 15pin to terminal board diagram in the 380 manual, with dual MDP switches (on & start/stop), turned out to be -very- helpful. I drew up a diagram of it in the same layout as my 370 diagram and was able to correlate every wire by name and function, so now I have the Monoplex to 15pin wiring confirmed. But it does not account for the 3 r/v wires to the fuse, or the wire pair on the hour meter.

Baby steps....

Drawings so far attached.

The Monoplex, fire suppression, and remote switching is entirely a Sea Ray engineered configuration.

John E3

Active Member

And appears to include genset control mods, too!The Monoplex, fire suppression, and remote switching is entirely a Sea Ray engineered configuration.

It seems I may be the first person to swap out a BCGTC with a BCGB.

Had I put this effort into swapping the 9.6 generator to the BCGB engine (+ governor and crank pulley), I would have been done by now. But I was really liking the 3600 to 1800 rpm change. Plus the plan was to pull the old and insert the new at the same time as the boat has to be moved to get access for a boom. It's a 20+ foot reach into the cabin, and the stern is facing water, 10ft away.

Yes to what Westerbeke concurs with. Like the addition of an oil pressure switch for the Systems Monitor.And appears to include genset control mods, too!

John E3

Active Member

The BCGTC westerbeke manual actually notes the switch specifically for Sea Ray and the wire is not part of the harness. The BCGB came from a Chris Craft and has the switch with it's own location in the 15pin connector, suggesting it was a standard feature in this model.Yes to what Westerbeke concurs with. Like the addition of an oil pressure switch for the Systems Monitor.

John E3

Active Member

I pulled the entire genset control and harness out of the boat, traced wires and found where they tapped into it. They pulled one end of the fuse quick connect off, connected that wire to a 12ga red in the harness to the boat, and the triple r/v wires from the harness to the fuse. And, they moved 1 wire on the circuit breaker to the other terminal of the ckt brkr, which results in the built in charger not being protected by it. It now feeds the battery directly. That change seems to not accomplish any actual purpose, aside from removing the charger protection.

The r/v wire off the hour meter into the harness is still a mystery. Opening the harness to the genset is next.

My Halon 'system', ie cylinder with switch has different colors from the wiring diagram, entirely. It's not mentioned anywhere in my manuals, nor more than in 1 square with 2 wires in the wiring diagram, but if I had a Halon Module, where would I find it? There is a water tight metal box on the stbd stringer next to the batteries, and another inside a panel below the main electrical panels with the anti corrosion modules, and stereo Amp, but that one looks like it has 120v wiring to it and warning stickers to match.

I could just replicate these mods on the BCGB, but that panel has zero room/clearance inside. The 15pin connector has 6 unused locations I could repurpose, but I only bought pins for the connector going to it. Shipping is 15 times the pin cost (0.25 each x6). Ugh

The r/v wire off the hour meter into the harness is still a mystery. Opening the harness to the genset is next.

My Halon 'system', ie cylinder with switch has different colors from the wiring diagram, entirely. It's not mentioned anywhere in my manuals, nor more than in 1 square with 2 wires in the wiring diagram, but if I had a Halon Module, where would I find it? There is a water tight metal box on the stbd stringer next to the batteries, and another inside a panel below the main electrical panels with the anti corrosion modules, and stereo Amp, but that one looks like it has 120v wiring to it and warning stickers to match.

I could just replicate these mods on the BCGB, but that panel has zero room/clearance inside. The 15pin connector has 6 unused locations I could repurpose, but I only bought pins for the connector going to it. Shipping is 15 times the pin cost (0.25 each x6). Ugh

At the helm there should be a SeaFire bypass switch with a couple of lamps on it and an alarm.

The wires from that switch assembly route to the SeaFire relay module.

The wires from the fire suppression bottle route to the relay module.

On my 400DA it was behind the helm gauges; on my 52DB it is inside of the main circuit breaker panel in the lazarette.

The wires from that switch assembly route to the SeaFire relay module.

The wires from the fire suppression bottle route to the relay module.

On my 400DA it was behind the helm gauges; on my 52DB it is inside of the main circuit breaker panel in the lazarette.

John E3

Active Member

Nope, nothing like that at the helm. I think the wiring diagram is misleading.At the helm there should be a SeaFire bypass switch with a couple of lamps on it and an alarm.

The wires from that switch assembly route to the SeaFire relay module.

The wires from the fire suppression bottle route to the relay module.

On my 400DA it was behind the helm gauges; on my 52DB it is inside of the main circuit breaker panel in the lazarette.

The Automatic Shutdown is required on diesel powered boats. I had thought Sea Ray also installed on all of the gasoline powered larger boats also. I've been on a couple of the AC's in our marina and they had the system. But I guess I'm wrong. Need someone else to input on this.Nope, nothing like that at the helm. I think the wiring diagram is misleading.

I assume therefore the wires from your fire suppression bottle lead to nowhere?

John E3

Active Member

The wires go into the bilge harness above the genset area. I'm going see if I find reference to a blk/grn anywhere in the drawings.

I went through the parts list too, and only found the 300sqft bottle listed. I did notice this description "harness, 400DA-97 gen monoplex ctnl construct " under the "Westerbeke gas 9.0" parts list. The list has the genset listed as a 9.6.

The halon bottle is in the engineroom section under not shown.

I went through the parts list too, and only found the 300sqft bottle listed. I did notice this description "harness, 400DA-97 gen monoplex ctnl construct " under the "Westerbeke gas 9.0" parts list. The list has the genset listed as a 9.6.

The halon bottle is in the engineroom section under not shown.

John E3

Active Member

I have figured out how they spliced into the genset with the wires from the harness, although I can't say I know where any of the wires go in the boat. I'm going to assume for now that since it worked before, it should still work with the BCGB.

The 2 primary changes were to the Fuse/Power, and an addon wire.

Change 1 - The battery wire and the charger wire are connected directly together, instead of through the circuit breaker as originally set up in the BCGTC model. The BCGB is this way by default. The circuit breaker now only protects the fused power to the gen-set control, and the starter solenoid (not fused). There is no obvious reason for having done this, except possibly in the case of the breaker popping, and the battery charger in the gen-set continuing to power the control, and gen-set, with the battery disconnected. This no longer protects the battery on overcurrent from the charger, however.

Change 2 - The circuit breaker was disconnected from the fuse and wires from the harness connected to those 2 points. This puts those wires in series with the power going to the control. This appears to be how they stop the gen-set. All "stop" switches, either inside the gen-set, or in each remote switch does exactly this, cutting off 12v to the control from the fuse.

The Addon wire is perplexing. It is connected to the hot side of the Hour Meter, which is in parallel with every device needed for the gen-set to run: fuel solenoid, fuel pump, coil, powered via the run relay from the fuse. Again, the "stop" switches are all in series with this power to the Relay, and the overspeed circuit, temp & oil pressure switches in the control too. This same connection is also available on 2 pins on the connector, one of which goes to the Monoplex "run indicator". Given that this wire is already available at the monoplex makes this addon connection seem very odd.

Unfortunately it's not getting installed for at least a month, so I won't know for sure it all works, but it's effectively connected the exact same way.

The 2 primary changes were to the Fuse/Power, and an addon wire.

Change 1 - The battery wire and the charger wire are connected directly together, instead of through the circuit breaker as originally set up in the BCGTC model. The BCGB is this way by default. The circuit breaker now only protects the fused power to the gen-set control, and the starter solenoid (not fused). There is no obvious reason for having done this, except possibly in the case of the breaker popping, and the battery charger in the gen-set continuing to power the control, and gen-set, with the battery disconnected. This no longer protects the battery on overcurrent from the charger, however.

Change 2 - The circuit breaker was disconnected from the fuse and wires from the harness connected to those 2 points. This puts those wires in series with the power going to the control. This appears to be how they stop the gen-set. All "stop" switches, either inside the gen-set, or in each remote switch does exactly this, cutting off 12v to the control from the fuse.

The Addon wire is perplexing. It is connected to the hot side of the Hour Meter, which is in parallel with every device needed for the gen-set to run: fuel solenoid, fuel pump, coil, powered via the run relay from the fuse. Again, the "stop" switches are all in series with this power to the Relay, and the overspeed circuit, temp & oil pressure switches in the control too. This same connection is also available on 2 pins on the connector, one of which goes to the Monoplex "run indicator". Given that this wire is already available at the monoplex makes this addon connection seem very odd.

Unfortunately it's not getting installed for at least a month, so I won't know for sure it all works, but it's effectively connected the exact same way.

What?

There are no fuses or circuit breakers in the battery cabling. First the generator's battery must go through a battery disconnect switch. The ship's AC battery charger is on the battery side of that disconnect switch. The switched battery cable, from that disconnect, routes directly to the generator's starter motor solenoid. That switched cable and the battery cable to the switch are not fused and consequently must have a secondary sheathing; SR uses that corrugated wire loom for that purpose.

The generator's alternator Bat terminal is directly wired to the battery cable termination on the starter solenoid.

Then finally the generator's control power comes also from that battery termination on the starter solenoid and that is fused or has a circuit breaker.

There are no fuses or circuit breakers in the battery cabling. First the generator's battery must go through a battery disconnect switch. The ship's AC battery charger is on the battery side of that disconnect switch. The switched battery cable, from that disconnect, routes directly to the generator's starter motor solenoid. That switched cable and the battery cable to the switch are not fused and consequently must have a secondary sheathing; SR uses that corrugated wire loom for that purpose.

The generator's alternator Bat terminal is directly wired to the battery cable termination on the starter solenoid.

Then finally the generator's control power comes also from that battery termination on the starter solenoid and that is fused or has a circuit breaker.

John E3

Active Member

Yes, you are 100% correct. I did not elaborate on all that which is between the battery and circuit breaker. The genset charger goes to the circuit breaker, then from the same terminal, to the Battery connection on the solenoid. From there it goes to the disconnect switch, then to the battery (and main charger). The genset charger was connected to the other side of the circuit breaker, as delivered from Westerbeke. ie Change 1 as noted. - Update - this is not correct. Somewhere I was lead to believe that the breaker protected the charging/battery circuit, but it in fact never did. This is as is from the factory.

From there, the 12v passes thru the Circuit Breaker to the fuse & K1 (start) relay. So the circuit breaker protects the genset, K1 (start) relay & monoplex (12v to the boat wiring now). The fuse further protects the control circuits, getting 12v back from the boat wiring. ie Change 2 as noted.

An Open Connection between the 12v to the harness, and 12v return from the harness is the only way to stop the genset now. Or the genset stop switch. On the diagram attached, open the line at the top of the fuse, and connect the 2 boat wires to the open connections. 12v from breaker to supply the power to the harness, and 12v returning to the fuse to supply the control circuit. Opening the connection stops the genset, just like the stop sw below the fuse does.

From there, the 12v passes thru the Circuit Breaker to the fuse & K1 (start) relay. So the circuit breaker protects the genset, K1 (start) relay & monoplex (12v to the boat wiring now). The fuse further protects the control circuits, getting 12v back from the boat wiring. ie Change 2 as noted.

An Open Connection between the 12v to the harness, and 12v return from the harness is the only way to stop the genset now. Or the genset stop switch. On the diagram attached, open the line at the top of the fuse, and connect the 2 boat wires to the open connections. 12v from breaker to supply the power to the harness, and 12v returning to the fuse to supply the control circuit. Opening the connection stops the genset, just like the stop sw below the fuse does.

Attachments

John E3

Active Member

An update on this situation. I got the genset physically installed a couple months ago, but the final control wiring is still to be connected, hopefully this week. Maybe tonight, I will be firing it up the first time in the boat, with the local switches. I can then load it down and see how it goes. I had another thread where I was looking for real world feedback on this unit. I was testing it in the shop with 4 1500W heaters, and almost stalled it when I turned on #4. That was 4500 -> 6000w, for a 7kw unit.

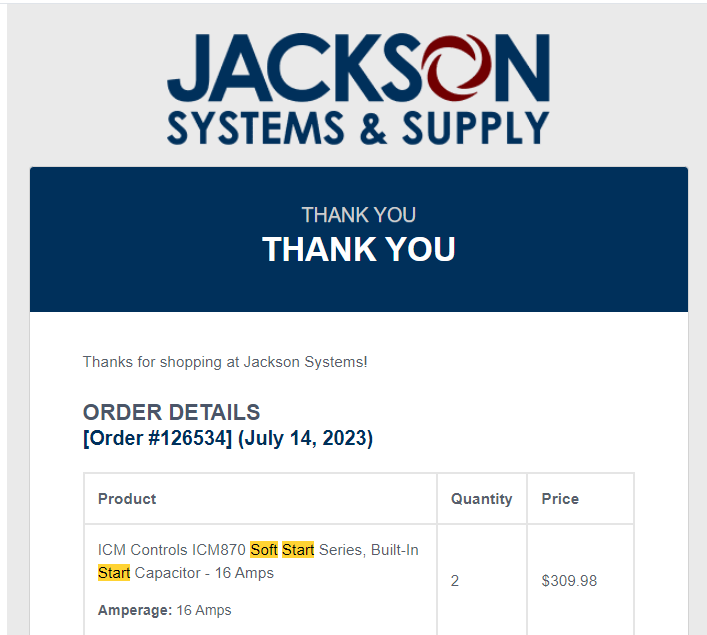

In all likelihood that near stall would have probably triggered other systems in the boat to go offline, such as AC. I have 3 AC units, 2 @7kbtu, and 1 at 16k. The 7's run around 7-8amps, the 16 @16amps. But when the 16k kicks on, the 50amp meter pegs hard over 50. I doubt this 7kw genset will be able to start it, so a soft start is probably needed. The 7's seem to peak at about 20 on the gauge. The actual spike could be higher but it's so fast it only gets to 20. The other unit buries the needle for 1-2 seconds, above 50.

I also finally figured out what the 2 extra mystery wires are, which were jumpered onto the hour meter, they feed the fuel line solenoid from the tank. All 3 fuel solenoids are missing from the wiring diagrams, and I had no clue how to energize it for testing, other than some clip leads to the battery. Problem solved. I thought these 2 wires went to the system monitor. Nope. These 2 wires drove me insane trying to map the control wires from one genset to the other. In the end I had them routed to equivalent pins on the remote connector, but still clueless what they did. This is still valid, but now I know what they are for. Had I figured this out way back then I would have saved a ton of time, and pages of diagrams of potential connections.

A hydrolocked port engine in the yard kinda derailed all other work a while back. Nothing 6 weeks, 2 new heads, and new exhaust manifolds and risers couldn't fix. Major sea water intrusion into the exhaust chamber at the top of the manifold. It had been leaking so long 1/4" of the iron is missing between the water jacket and exhaust port. I can't believe this engine didn't hydrolock after every run. 5 of 8 cylinders did have indications of water in the cylinders. The other engine may be in a similar state, so good chance of longblock there, and a shortblock on the one with new heads, this fall. That's a salon ceiling/helm floor opening ordeal. Ugh. Thankfully I have waaaaayyyy more room around them to work than a lot of others do. This was particularly helpful when I had to remove the fully assembled outboard manifold/riserblock/elbow to install the coolant plug between the center cylinders. The manifold went in in 3 pcs cause it's under the floor/hatch edge and you can't get to the long studs, or get the parts on the studs once the manifold bolted to the head. Nightmare! Then I made the same mistake on the inboard side! Same deal, but it's the hatch support beam above this one.

My wife found a perfect quote that describes my project life, to the power of 10 on the engine work (like 5 hrs with a 5lb sledge to remove 1 manifold from the rusted studs after many hours getting the bolt heads cut off):

"Every twenty minute job is one broken bolt away from becoming a three day ordeal"

No truer words have even been spoken! We have called this the "our last name" curse, from my father, me, my late brother and his son. Nothing ever goes as planned, or in the allotted time, no matter how trivial the project is.

In my case here it was 5 broken bolts and 5 rusted off heads. That's about right, 10 bolts x 3 days is 30 days, just to cover getting it apart!

In all likelihood that near stall would have probably triggered other systems in the boat to go offline, such as AC. I have 3 AC units, 2 @7kbtu, and 1 at 16k. The 7's run around 7-8amps, the 16 @16amps. But when the 16k kicks on, the 50amp meter pegs hard over 50. I doubt this 7kw genset will be able to start it, so a soft start is probably needed. The 7's seem to peak at about 20 on the gauge. The actual spike could be higher but it's so fast it only gets to 20. The other unit buries the needle for 1-2 seconds, above 50.

I also finally figured out what the 2 extra mystery wires are, which were jumpered onto the hour meter, they feed the fuel line solenoid from the tank. All 3 fuel solenoids are missing from the wiring diagrams, and I had no clue how to energize it for testing, other than some clip leads to the battery. Problem solved. I thought these 2 wires went to the system monitor. Nope. These 2 wires drove me insane trying to map the control wires from one genset to the other. In the end I had them routed to equivalent pins on the remote connector, but still clueless what they did. This is still valid, but now I know what they are for. Had I figured this out way back then I would have saved a ton of time, and pages of diagrams of potential connections.

A hydrolocked port engine in the yard kinda derailed all other work a while back. Nothing 6 weeks, 2 new heads, and new exhaust manifolds and risers couldn't fix. Major sea water intrusion into the exhaust chamber at the top of the manifold. It had been leaking so long 1/4" of the iron is missing between the water jacket and exhaust port. I can't believe this engine didn't hydrolock after every run. 5 of 8 cylinders did have indications of water in the cylinders. The other engine may be in a similar state, so good chance of longblock there, and a shortblock on the one with new heads, this fall. That's a salon ceiling/helm floor opening ordeal. Ugh. Thankfully I have waaaaayyyy more room around them to work than a lot of others do. This was particularly helpful when I had to remove the fully assembled outboard manifold/riserblock/elbow to install the coolant plug between the center cylinders. The manifold went in in 3 pcs cause it's under the floor/hatch edge and you can't get to the long studs, or get the parts on the studs once the manifold bolted to the head. Nightmare! Then I made the same mistake on the inboard side! Same deal, but it's the hatch support beam above this one.

My wife found a perfect quote that describes my project life, to the power of 10 on the engine work (like 5 hrs with a 5lb sledge to remove 1 manifold from the rusted studs after many hours getting the bolt heads cut off):

"Every twenty minute job is one broken bolt away from becoming a three day ordeal"

No truer words have even been spoken! We have called this the "our last name" curse, from my father, me, my late brother and his son. Nothing ever goes as planned, or in the allotted time, no matter how trivial the project is.

In my case here it was 5 broken bolts and 5 rusted off heads. That's about right, 10 bolts x 3 days is 30 days, just to cover getting it apart!

370Dancer

Well-Known Member

- Oct 2, 2006

- 2,486

- Boat Info

- 1998 370 Sundancer

- Engines

- 380hp MAG MPI Gen VI with V drives

I just put soft starts on my 16K and 9K units. I can't even see the amp meter jump anymore when the compressors kick in. Will try on my 7.0 BCG this weekend, but I am sure it won't even bog down.

GO HERE: $150 each instead of the 350+ Micro air wants per unit.

GO HERE: $150 each instead of the 350+ Micro air wants per unit.

John E3

Active Member

I just put soft starts on my 16K and 9K units. I can't even see the amp meter jump anymore when the compressors kick in. Will try on my 7.0 BCG this weekend, but I am sure it won't even bog down.

GO HERE: $150 each instead of the 350+ Micro air wants per unit.

Testing last night was better than I expected. It was able to start the 16k compressor, with no other load. It struggled only a few seconds, but I will still be looking at the soft starts for sure.