Jon Schwartz

New Member

- Jul 27, 2017

- 11

- Boat Info

- 215 Sea Ray Weekender

- Engines

- 5.0 Mercruiser I/O

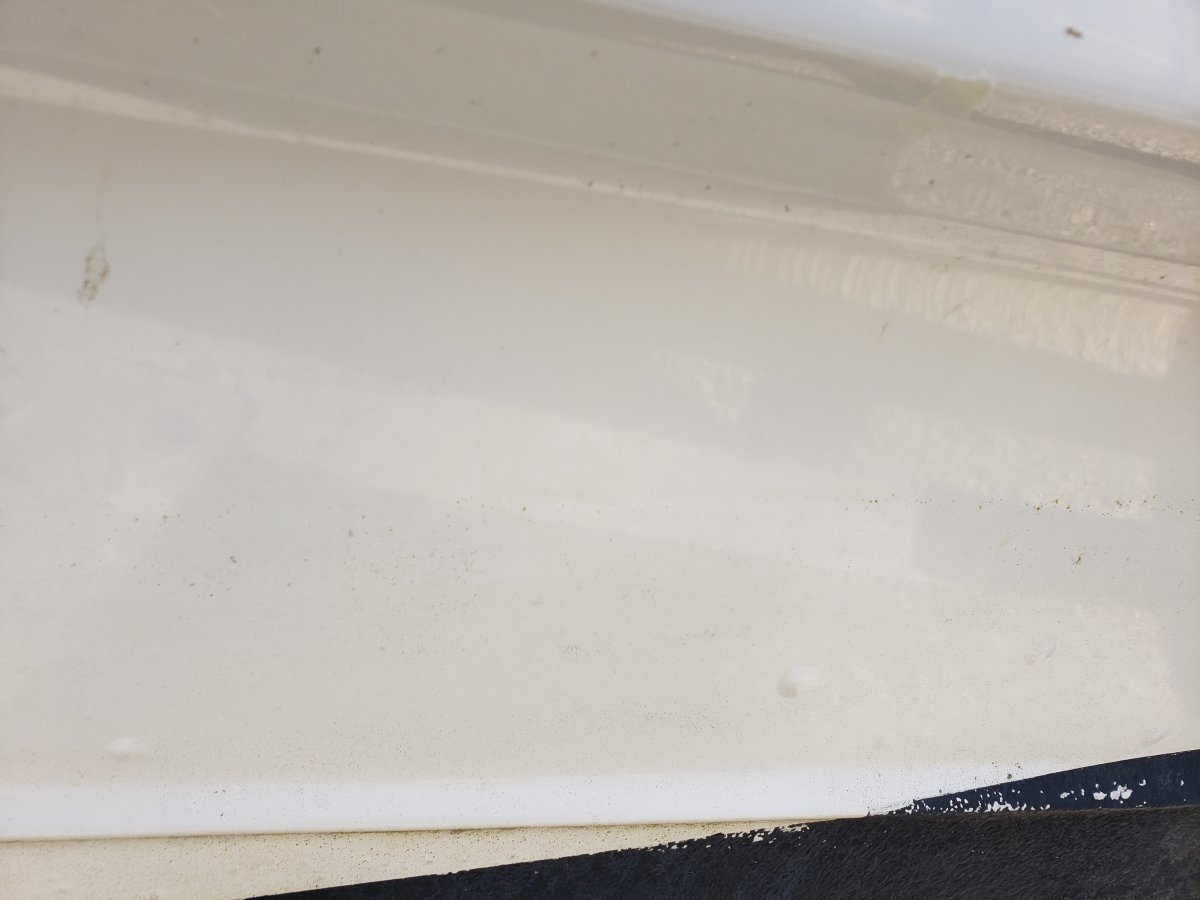

When I pulled my 2007 215 Weekender form the water last month, I noticed these different sized Blisters in the Gel coat at the water line, above the water line, and under the bottom paint. I suspect there is moisture in the hull is causing this. I also had noticed over the summer, while the boat was docked that it appeared as if there was extra weight in the bow, in that the stern sat a lot higher then it should have. Checking the bilges did not show any abnormal amounts of water. Isuspect i know the issue, but not the cause, so i am looking for some real knowledge and insight into this. What is the Hull core material made from? best guess of water infiltration other then the obvious locations, and potential fixes.. Highly recommend, lipstick on a pig, or leave it be? this boat only has 101 original hours, and was purchased from the original owner 3 years ago, when it had only 26 original hours. Boat was hardly used, and was mostly trailered. We

dunked it 3 years ago, and been pulling it every fall, giving it some good TLC

dunked it 3 years ago, and been pulling it every fall, giving it some good TLC