- Jun 5, 2016

- 5,624

- Boat Info

- 410 Sundancer

2001

12" Axiom and 9" Axiom+ MFD

- Engines

- Cat 3126 V-Drives

Planning for the move north to Atlanta. I will have to reinstall the props. Planning in advance to have the tools and proper parts on hand.

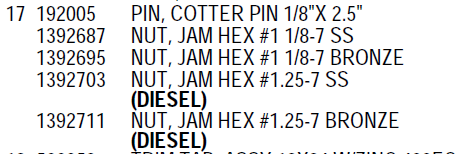

Sea Ray Parts Manual for the 2001 410 with diesel option shows 1.25" Hex Jam Nuts.

Can anyone confirm this is the correct size nut?

Also...what wrenches do you use/recommend? Do I need a persuader bar? I'm 200lbs + and with a 18"-24" arm, that's a lot or torque.

Sea Ray Parts Manual for the 2001 410 with diesel option shows 1.25" Hex Jam Nuts.

Can anyone confirm this is the correct size nut?

Also...what wrenches do you use/recommend? Do I need a persuader bar? I'm 200lbs + and with a 18"-24" arm, that's a lot or torque.

Last edited: