emckissack@hotmail.com

Member

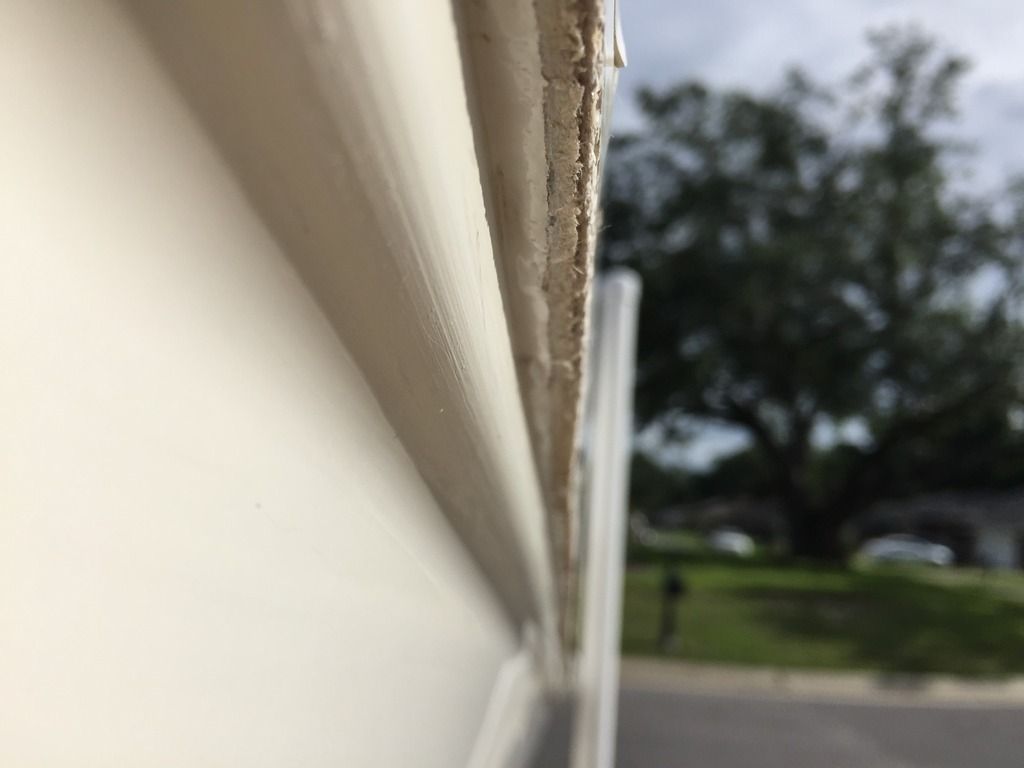

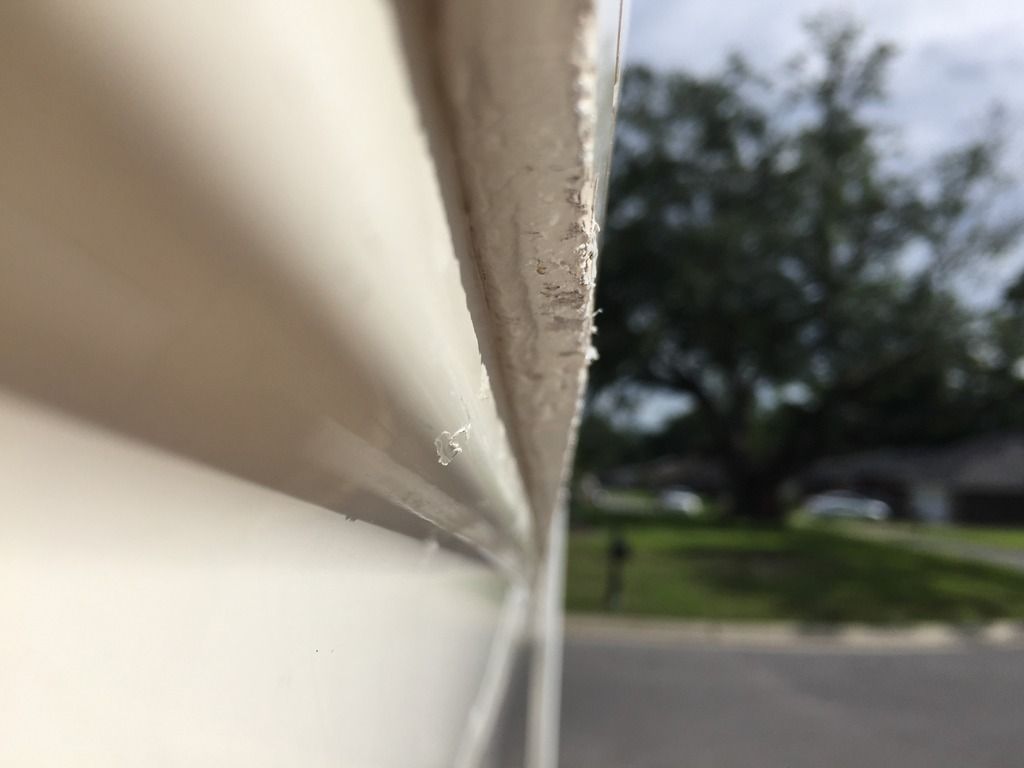

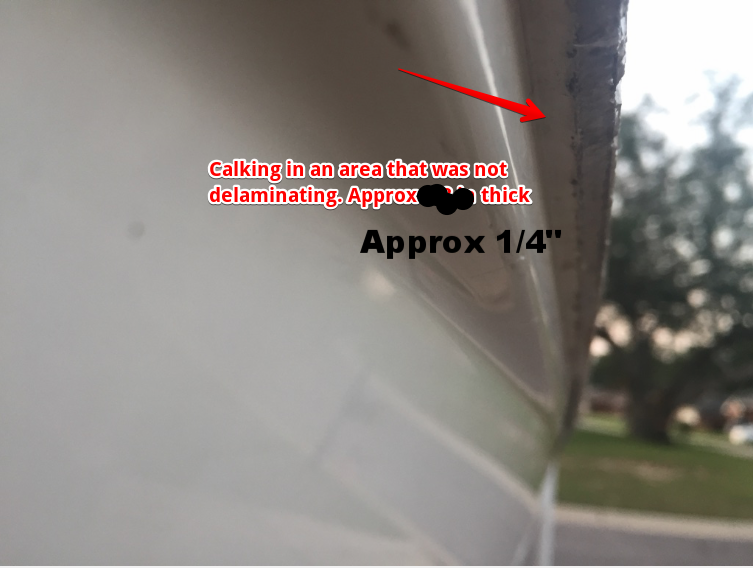

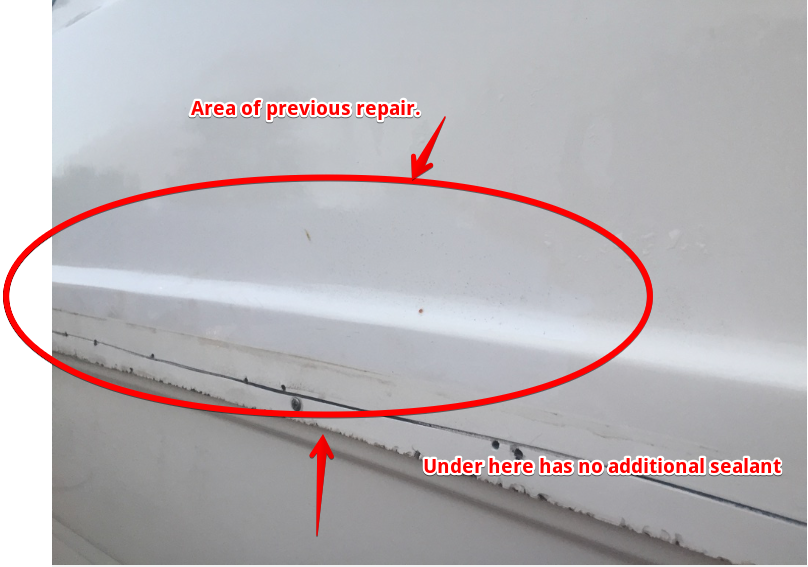

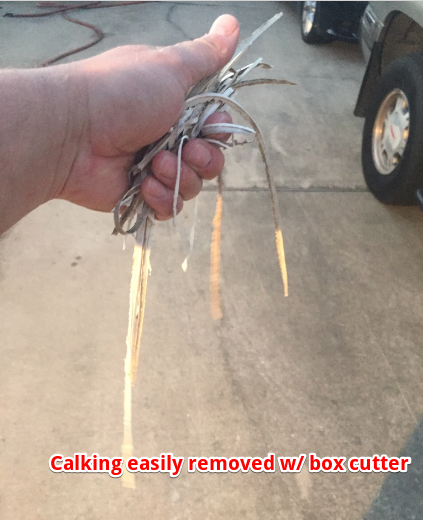

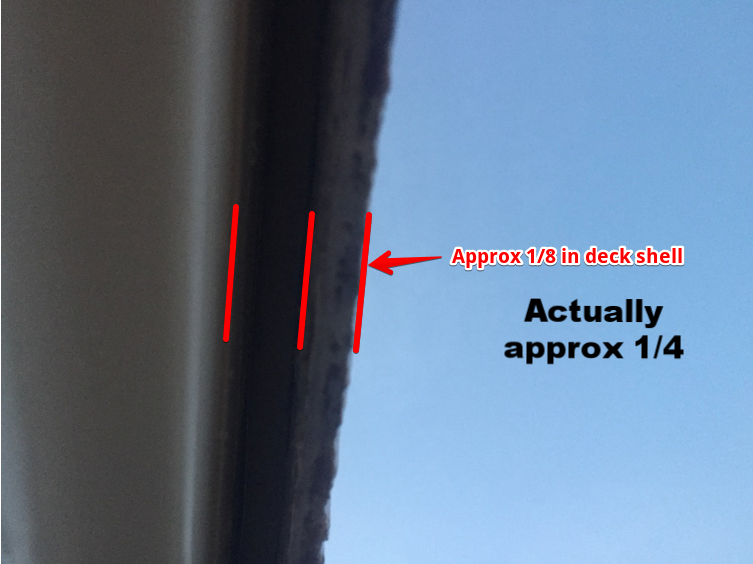

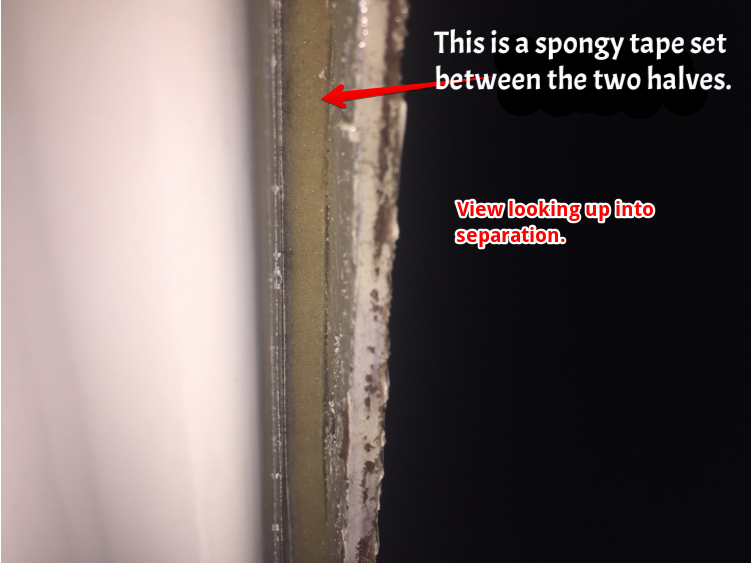

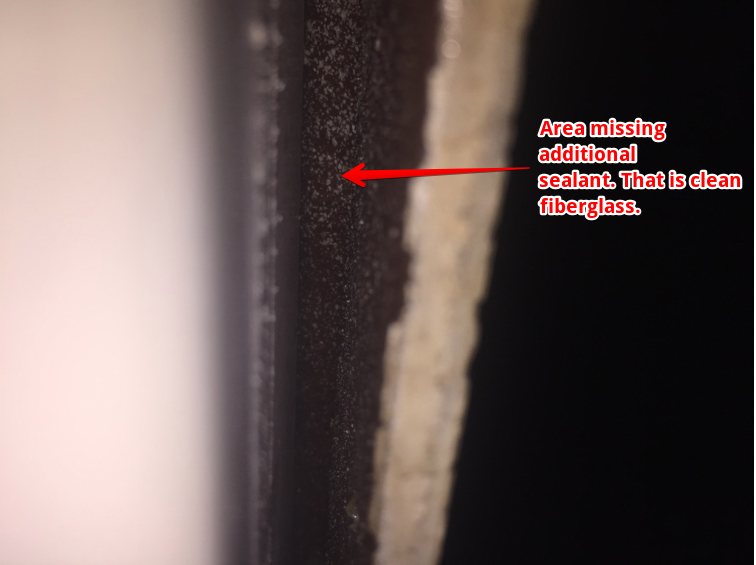

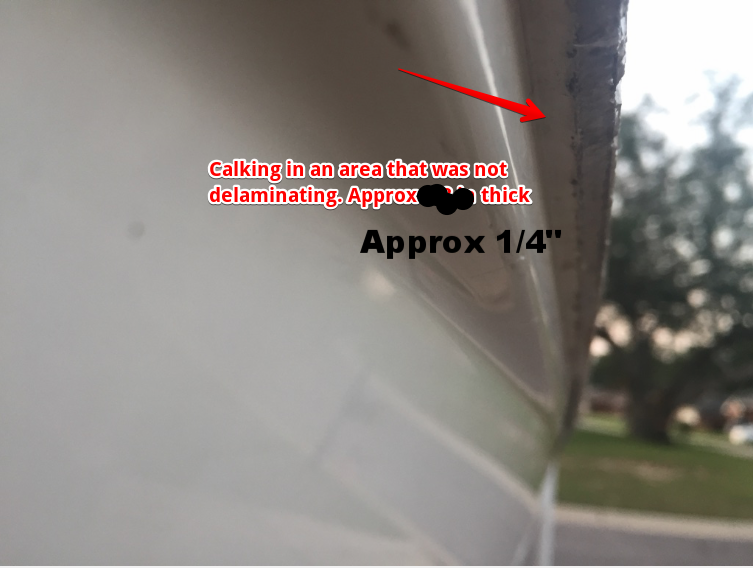

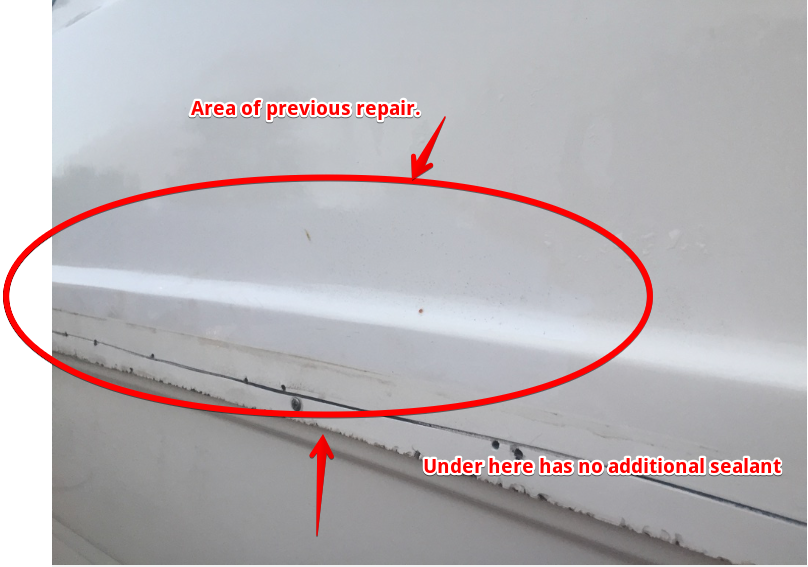

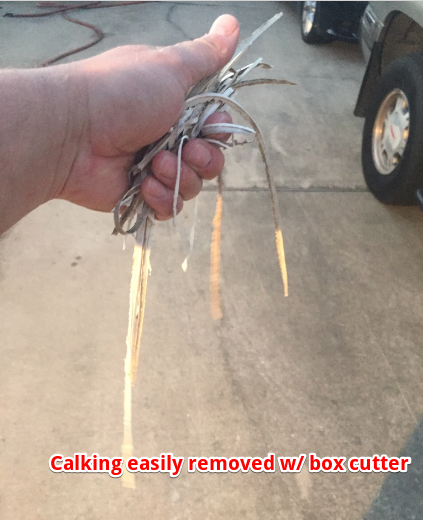

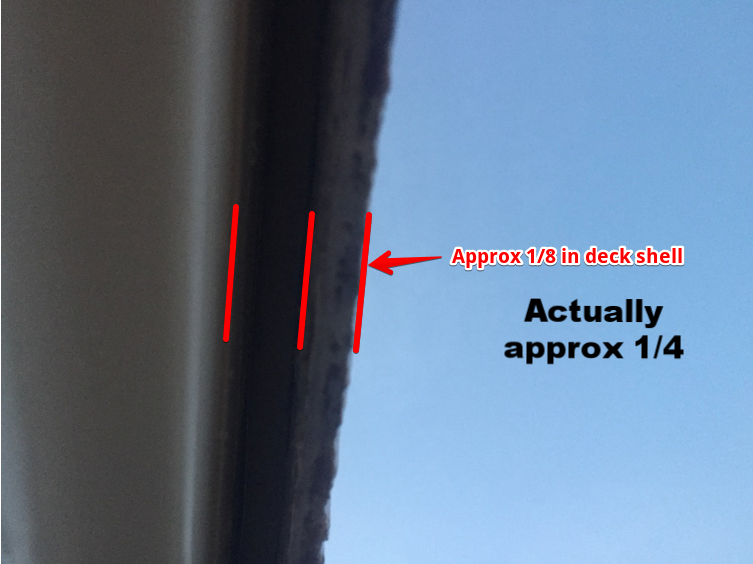

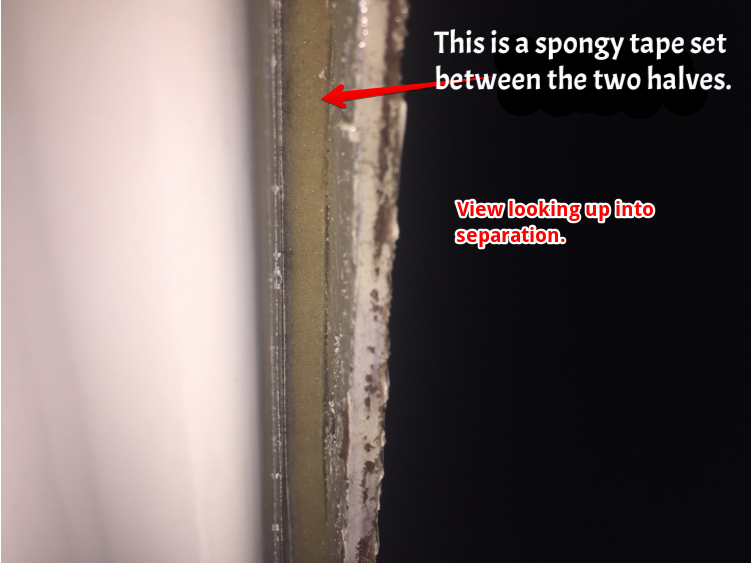

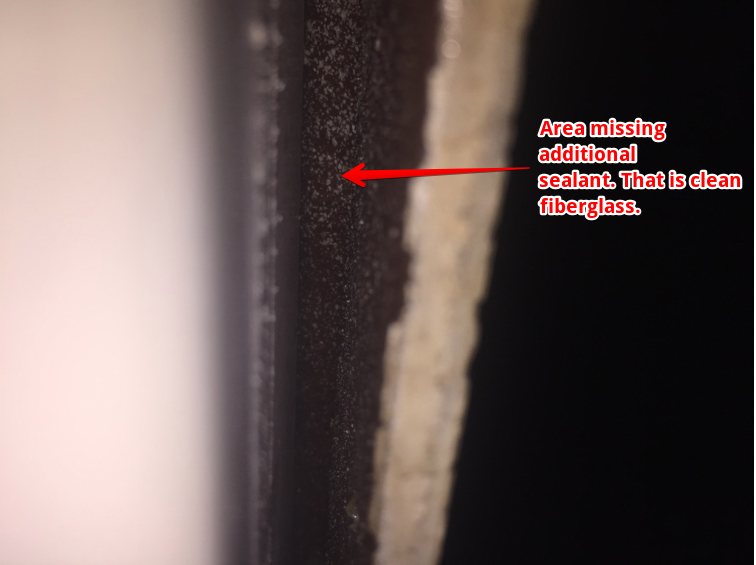

So I have been trying to track down a leak into the lower step area in the front cabin area. I noticed that the carpet was getting wet with sea water after sleeping overnight the last few times we stayed in the boat. I initially thought that maybe I wasn't screwing in the drain plug tight enough but took care of that and still managed to have sea water entering. I checked under the stair step where the shower sump is and after cooking up the water I found that the water is coming into the lower step area through the screws that hold down the support that holds the floating entry step. (Pics attached) Throughout the following day, I noticed the water receding and eventually drained from under the stairs presumably back through the screws??. This past weekend, while sleeping in the cabin, (2 adults and 1 child) I still had sea water enter under the stairs but seemed to be a little worse this time, approx an inch of standing water, and thinking about it, we had a bit more bow porpoising on our ride out which may help in determining where the water is coming from. Again, after cleaning up the water would only seep back into the cabin but mostly stopped from coming in from under the stair support which leads me to believe there is not a steady source of water entering the boat...The whole time the bilge never reached the level to be able to pump anything overboard and we were out for 24Hrs. On the way back in, we had an increased amount of porpoising due to 2-3 ft chop we were plaining through. Once back at the marina, I manually turned on the bilg pump and it pumped maybe several gallons of water overboard before stoping. So when I got back home I began to check the back of sleeping bunk and found that the back wall down by the floor was wet on the port side and so was the sleeping pad that was up against the wall. I then checked outside at the rubrail area and began to hear hollowness behind a repair in the fiberglass just above the port side rubrail midship. I decided to remove the rubrail and found the following. The screws that were holding the hull and deck together were not pulled tight and it looked as though sealant was applied to fill the gap instead of tightening down the screws to close the gap. Is this normal?

http://s66.photobucket.com/user/emckissack/slideshow/Sea Ray leak

VIDEO:

I have read the following posts about this issue and will most likely follow the same procedure.

http://clubsearay.com/showthread.php/83083-Resealing-the-hull-to-deck-joint

Questions:

1. How would water get into the area under where the step support is attached. Is it possible that it could be entering from the side?

2. I have read that 3M 5200 should be used to reseal the hull to the deck. Can anyone confirm if this is what I should use based on experience or is there something else I should use? another option is Life Caulk???

3. When I go to seal everything up, should I squeeze the calking into the gap first then run the screws back into the fiberglass and tighten them down squeezing the calking together and not leave the gap that was there previously?

Any insight and advise will be much appreciated.

http://s66.photobucket.com/user/emckissack/slideshow/Sea Ray leak

VIDEO:

I have read the following posts about this issue and will most likely follow the same procedure.

http://clubsearay.com/showthread.php/83083-Resealing-the-hull-to-deck-joint

Questions:

1. How would water get into the area under where the step support is attached. Is it possible that it could be entering from the side?

2. I have read that 3M 5200 should be used to reseal the hull to the deck. Can anyone confirm if this is what I should use based on experience or is there something else I should use? another option is Life Caulk???

3. When I go to seal everything up, should I squeeze the calking into the gap first then run the screws back into the fiberglass and tighten them down squeezing the calking together and not leave the gap that was there previously?

Any insight and advise will be much appreciated.

Last edited: