- Jun 5, 2016

- 5,617

- Boat Info

- 410 Sundancer

2001

12" Axiom and 9" Axiom+ MFD

- Engines

- Cat 3126 V-Drives

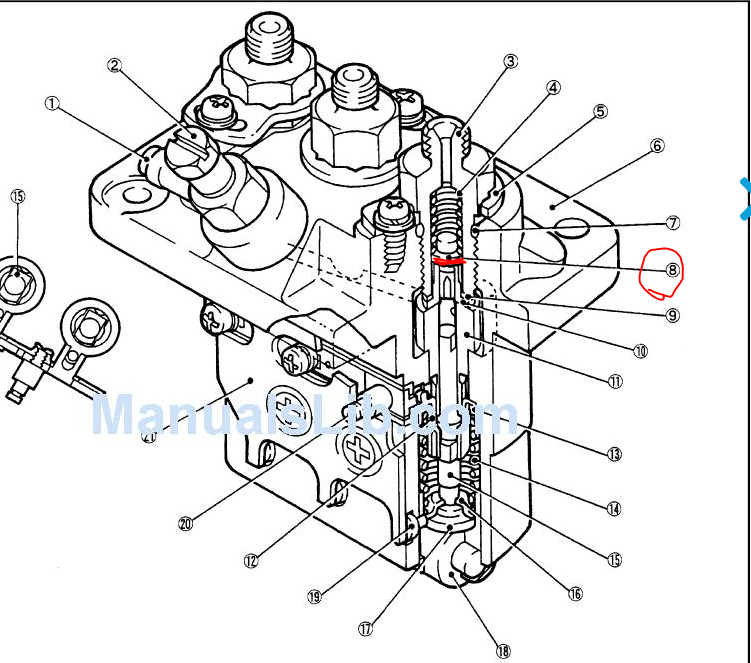

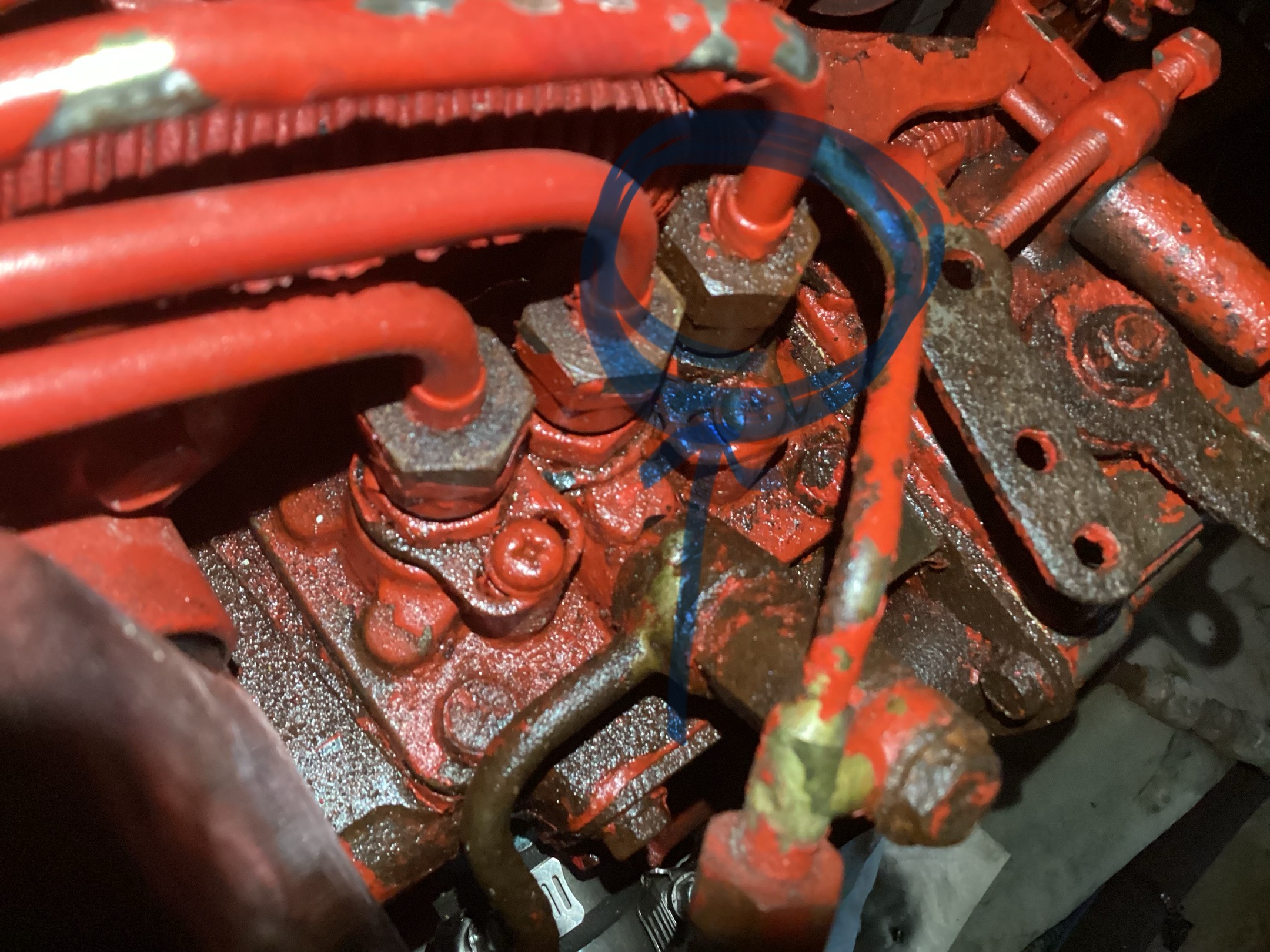

Been noticing a small amount of diesel wetting the top of the injector pump. Looks to be leaking from under the delivery valve. Gets worse under a heavier load. There is an o ring in there, so at 23-24 years old, maybe getting old/worn and in need of some service.

Anybody ever pull the delivery valves out for service, or should I pull the whole pump and either rebuild or replace?

U

Anybody ever pull the delivery valves out for service, or should I pull the whole pump and either rebuild or replace?

U