rondds

Well-Known Member

- Oct 3, 2006

- 8,859

- Boat Info

- 2001 380DA

- Engines

- Merc 8.1s (2008)...Hurth ZF 63 V-drives...WB 7.0 BCGD (2013), Garmin 8208 & 740 MFDs, GMR 24xHD dome

Got back in from a 2 1/2 hour run, opened the hatch to find water in the bilge sumps. Checked the dripless and the stbd was leaking a healthy stream and the shaft was too hot to touch.

Had the boat hauled and autopsy reveals that the entire plastic housing that slides inside the blue hose tube had melted from the heat, presumably from a lack of cooling water. I called Tides and they confirmed that is likely what had happened. The tech stated that they like to see 1g per minute at idle. I started the boat on land and ran it from a bucket and was getting less than 1/2 gallon per minute.

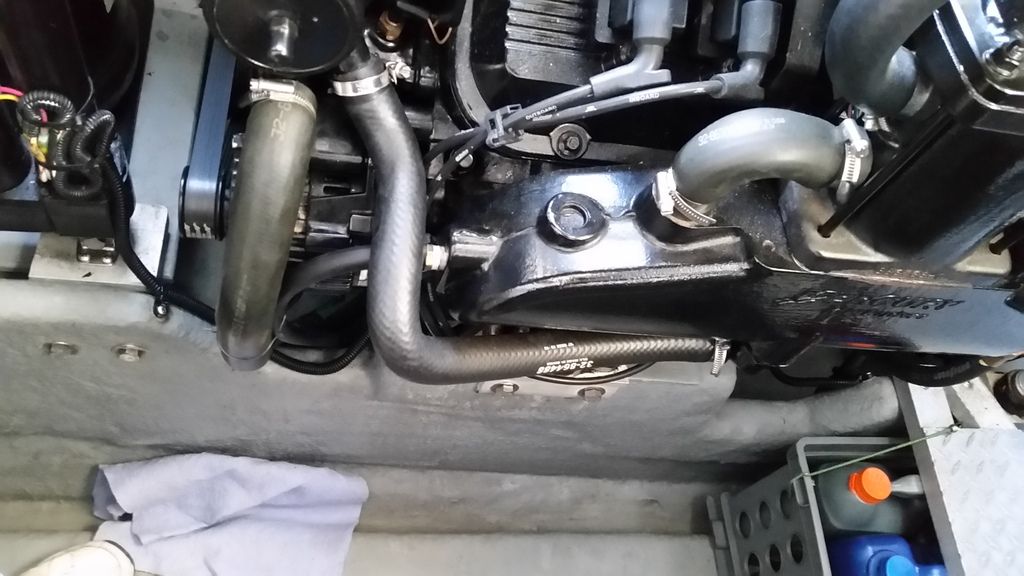

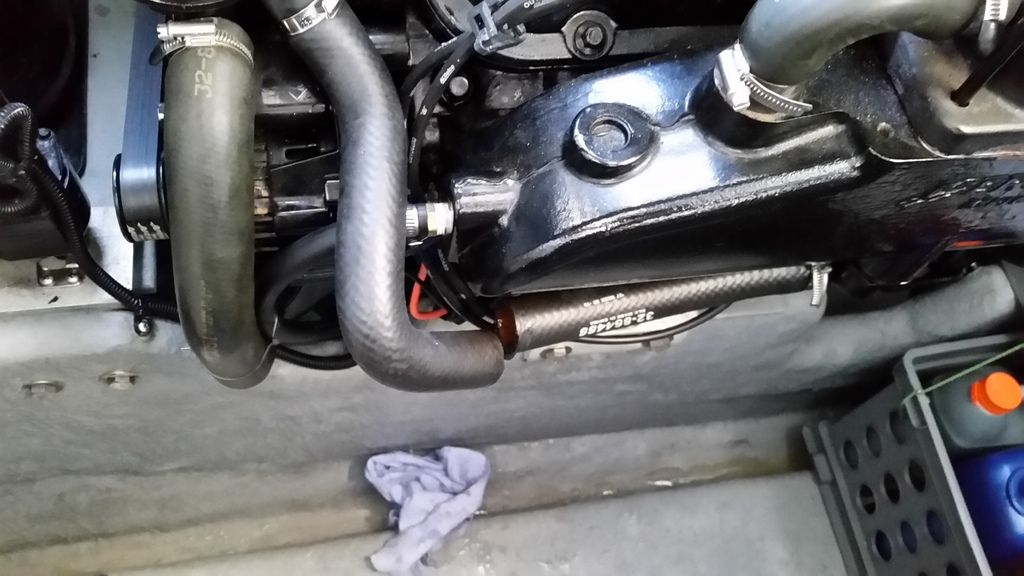

On my engines, the feed for the dripless water comes off the end of the exhaust manifold.

Has this happened to anyone else and if so what was the cause of the loss of cooling water? I might add that the boat ran fine during that entire trip, with both engines running at the similar temps. I have no idea when exactly the melting occurred - could have been minute one, or minute 125. But I do know that before that run, the engine room check revealed zero water and all was normal. The seal was not leaking prior to this event.

Had the boat hauled and autopsy reveals that the entire plastic housing that slides inside the blue hose tube had melted from the heat, presumably from a lack of cooling water. I called Tides and they confirmed that is likely what had happened. The tech stated that they like to see 1g per minute at idle. I started the boat on land and ran it from a bucket and was getting less than 1/2 gallon per minute.

On my engines, the feed for the dripless water comes off the end of the exhaust manifold.

Has this happened to anyone else and if so what was the cause of the loss of cooling water? I might add that the boat ran fine during that entire trip, with both engines running at the similar temps. I have no idea when exactly the melting occurred - could have been minute one, or minute 125. But I do know that before that run, the engine room check revealed zero water and all was normal. The seal was not leaking prior to this event.