Deuceornothing

New Member

So I have had a few posts on here in the last 9 months or so but I figured I would start at the beginning as I know some people can be discouraged about buying an older boat that needs some TLC.

I have been boating almost all of my 35 years of life and have never taken the easy road on anything it seams. Of course it was no different here. About a year ago I lost my job and decided I wanted to get into a different field. I wanted something that would allow me to control my destiny by how hard I worked. I became a financial advisor and have sworn to do the right thing for people no matter what and even that meant to walk away from serious commissions (I have done that several times). After going through all the training and taking all of the Federal and State tests I convinced my wife that my reward was going to be a 1983 Sea Ray 310 that I had my eye on. We bought the boat in April. There were several things wrong with her but nothing I thought I couldn't fix over the next year or so. I wanted inboards as I didn't want to have to have it hauled out for service. Everything was fine until Memorial day weekend. The boat had been making a noise that I just couldn't figure out what it was. It sounded like the tranny was going in and out of gear and idle speeds and if I bumped up the rpm's just a tad the noise would go away. Well little did I know it was the warning sound of a damper plate going bad. On the way back in to the dock she came apart. When i say came apart I mean the tranny broke off the engine and the flywheel cover was destroyed. We limped back to the dock on one engine and I started investigating.

It was a $100 part that broke that will end up costing so much more later on.

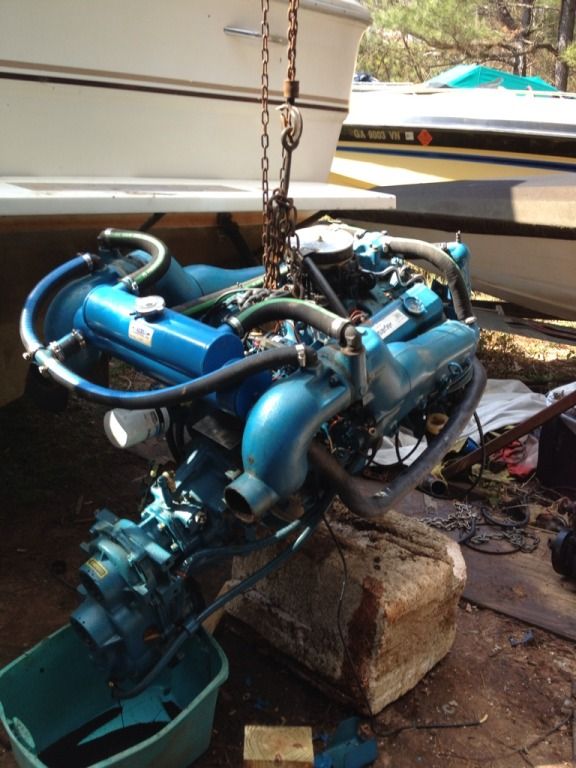

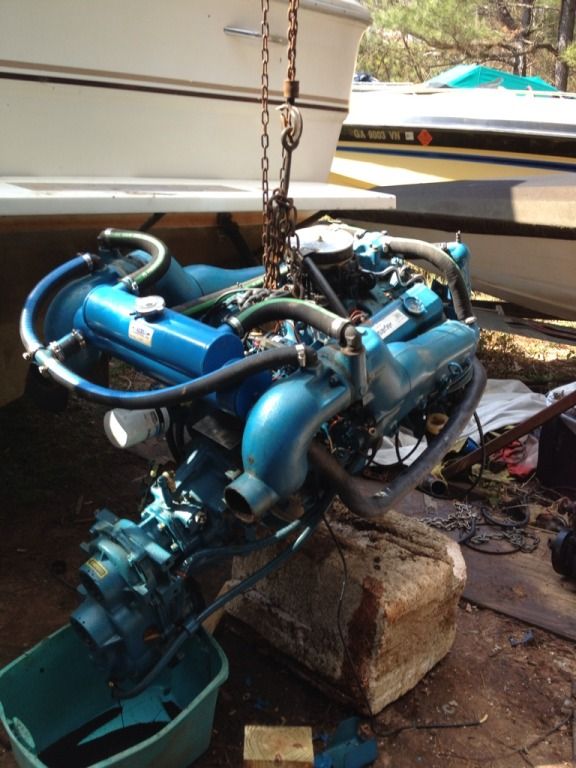

I order the parts and start to take things apart. Now I have pulled engines out of trucks before but never a boat. As it turns out it wasn't that bad but I was in for a long repair as I really couldn't afford to have it hauled out and the trailer that I could get it on needed repairs before it could handle something of my weight. So I improvised.

This was not the ideal way to do it but it was the only way I could figure out how to move the engine and repair it. It took a few days to fix everything but the next weekend we were back on the water.

She was fixed or so I thought. This is where I learned about alignment of an inboard engine. I thought since I put it right back in the same holes everything would be fine. I was wrong and with in a few hours of engine time the tranny began to leak fluid. Of course I thought the worst thinking that the housing was cracked and I was going to need a new tranny. Problem was they don't make these anymore and the new replacement it larger and there is now way a new one was fitting in the engine room.

The problem this time was the output shaft seal was leaking. which is at the bottom of the tranny and needs to have a torque of over 200 ft lb's on it. I could put my hand on it but there was no way I could get an impact on it or a large enough torque wrench. So we do the unthinkable again and take the engine back out. This time we remover the entire tranny from the boat and bring it up to the garage. The nut that is supposed to have 200+ ft lb's of torque comes off by hand. We inspect the casing and find no cracks. She goes back in the boat new seals and all.

At this time I know it needs to be aligned and hire a marina to co and do it. $360 later he says it's good. He was wrong but lucky for me I noticed a rubbing sound and we didn't try to move it. So I call the marina back and say hey this isn't right. They want to charge me another trip fee and another $120 per hour till they get it right. At this point I'm ready to fix it myself and I also wished I had paid with a credit card so I could stop payment but I paid with cash. I let it go as to me it was obvious they didn't know what they were doing.

Fast forward to this winter. Business is starting to pick up a little bit and I start my planning of what i want to do this winter. I know it needs to come out of the water and the trailer was finally fixed and ready for me. So if you remember I have the port engine I'm unable to use and the starboard engine has started making the noise the port engine did before it broke on me. So we have to tow it to the boat ramp. I did swim down and tie the port prop off so it wouldn't spin as I was afraid it would wear a oval in the stuffing box by turn as it was pulled through the water. So we get her over to the ramp and on the trailer. She was supposed to weight 13,000lbs so I figured it was going to be around 1,000 more. I was wrong again(see a pattern here). I have pulled many things in my life as I have a tractor trailer license but this was much heavier than we thought. We pulled the boat out with a 2500 chevy diesel in 4 wheel low and it almost stalled coming up the ramp. I was about to go hook another truck to it.

So now she is out and I have a bunch of stuff to do to her. Starting with pulling the starboard motor and replacing the damper plate. With the boat out of the water it only takes a day with the help of my brother.

I had a few other things that needed to be fixed while the engine was out. It was easier to get to the holding tank and vacuum pump and I needed new pressure switch and duck bills. Now I asked the place where I got the parts and they told me in this process I will not encounter and waste. Once again someone was wrong. I kind of counted on this one being full of ****. I could have hired someone at $125 an hour but I figured I could wash my hands really good and save a few hundred bucks.

The canvas needs a few zippers because of dry rot and I ripped up the floor down below. I will update the thread once I get to finishing that.

The swim platform I built in my garage out of white oak(yes I am aware of the risks) will be installed this weekend. I had a friend that welded new aluminium brackets for me and I just picked them up last night. Here are a few pic's but I have another thread just on the platform.

I also built a speaker box to go behind the kick panel on the port side of the boat. Stereo upgrade is in the works but here is the box.

So I have had a ton of help along the way. I have been very fortunate that I have several friends that have helped with this when I have needed some help. Overall I am very happy we bought the boat and I would do all of this over again if I had too. I would start to investigate any noises I hear sooner rather than later.

I have been told that those damper plates normally have a life expectancy of about 1000 hr's. So if your inboard is around those hrs and you hear it make a noise like it's going in and out of gear you may need to replace the damper plate. If anyone is around Lake Lanier that has a boat like mine, I would be happy to help in anyway that I can.

I have been boating almost all of my 35 years of life and have never taken the easy road on anything it seams. Of course it was no different here. About a year ago I lost my job and decided I wanted to get into a different field. I wanted something that would allow me to control my destiny by how hard I worked. I became a financial advisor and have sworn to do the right thing for people no matter what and even that meant to walk away from serious commissions (I have done that several times). After going through all the training and taking all of the Federal and State tests I convinced my wife that my reward was going to be a 1983 Sea Ray 310 that I had my eye on. We bought the boat in April. There were several things wrong with her but nothing I thought I couldn't fix over the next year or so. I wanted inboards as I didn't want to have to have it hauled out for service. Everything was fine until Memorial day weekend. The boat had been making a noise that I just couldn't figure out what it was. It sounded like the tranny was going in and out of gear and idle speeds and if I bumped up the rpm's just a tad the noise would go away. Well little did I know it was the warning sound of a damper plate going bad. On the way back in to the dock she came apart. When i say came apart I mean the tranny broke off the engine and the flywheel cover was destroyed. We limped back to the dock on one engine and I started investigating.

It was a $100 part that broke that will end up costing so much more later on.

I order the parts and start to take things apart. Now I have pulled engines out of trucks before but never a boat. As it turns out it wasn't that bad but I was in for a long repair as I really couldn't afford to have it hauled out and the trailer that I could get it on needed repairs before it could handle something of my weight. So I improvised.

This was not the ideal way to do it but it was the only way I could figure out how to move the engine and repair it. It took a few days to fix everything but the next weekend we were back on the water.

She was fixed or so I thought. This is where I learned about alignment of an inboard engine. I thought since I put it right back in the same holes everything would be fine. I was wrong and with in a few hours of engine time the tranny began to leak fluid. Of course I thought the worst thinking that the housing was cracked and I was going to need a new tranny. Problem was they don't make these anymore and the new replacement it larger and there is now way a new one was fitting in the engine room.

The problem this time was the output shaft seal was leaking. which is at the bottom of the tranny and needs to have a torque of over 200 ft lb's on it. I could put my hand on it but there was no way I could get an impact on it or a large enough torque wrench. So we do the unthinkable again and take the engine back out. This time we remover the entire tranny from the boat and bring it up to the garage. The nut that is supposed to have 200+ ft lb's of torque comes off by hand. We inspect the casing and find no cracks. She goes back in the boat new seals and all.

At this time I know it needs to be aligned and hire a marina to co and do it. $360 later he says it's good. He was wrong but lucky for me I noticed a rubbing sound and we didn't try to move it. So I call the marina back and say hey this isn't right. They want to charge me another trip fee and another $120 per hour till they get it right. At this point I'm ready to fix it myself and I also wished I had paid with a credit card so I could stop payment but I paid with cash. I let it go as to me it was obvious they didn't know what they were doing.

Fast forward to this winter. Business is starting to pick up a little bit and I start my planning of what i want to do this winter. I know it needs to come out of the water and the trailer was finally fixed and ready for me. So if you remember I have the port engine I'm unable to use and the starboard engine has started making the noise the port engine did before it broke on me. So we have to tow it to the boat ramp. I did swim down and tie the port prop off so it wouldn't spin as I was afraid it would wear a oval in the stuffing box by turn as it was pulled through the water. So we get her over to the ramp and on the trailer. She was supposed to weight 13,000lbs so I figured it was going to be around 1,000 more. I was wrong again(see a pattern here). I have pulled many things in my life as I have a tractor trailer license but this was much heavier than we thought. We pulled the boat out with a 2500 chevy diesel in 4 wheel low and it almost stalled coming up the ramp. I was about to go hook another truck to it.

So now she is out and I have a bunch of stuff to do to her. Starting with pulling the starboard motor and replacing the damper plate. With the boat out of the water it only takes a day with the help of my brother.

I had a few other things that needed to be fixed while the engine was out. It was easier to get to the holding tank and vacuum pump and I needed new pressure switch and duck bills. Now I asked the place where I got the parts and they told me in this process I will not encounter and waste. Once again someone was wrong. I kind of counted on this one being full of ****. I could have hired someone at $125 an hour but I figured I could wash my hands really good and save a few hundred bucks.

The canvas needs a few zippers because of dry rot and I ripped up the floor down below. I will update the thread once I get to finishing that.

The swim platform I built in my garage out of white oak(yes I am aware of the risks) will be installed this weekend. I had a friend that welded new aluminium brackets for me and I just picked them up last night. Here are a few pic's but I have another thread just on the platform.

I also built a speaker box to go behind the kick panel on the port side of the boat. Stereo upgrade is in the works but here is the box.

So I have had a ton of help along the way. I have been very fortunate that I have several friends that have helped with this when I have needed some help. Overall I am very happy we bought the boat and I would do all of this over again if I had too. I would start to investigate any noises I hear sooner rather than later.

I have been told that those damper plates normally have a life expectancy of about 1000 hr's. So if your inboard is around those hrs and you hear it make a noise like it's going in and out of gear you may need to replace the damper plate. If anyone is around Lake Lanier that has a boat like mine, I would be happy to help in anyway that I can.