PlayDate

Well-Known Member

Tom,

This is what I am reacting to:

Tom, @ttmott

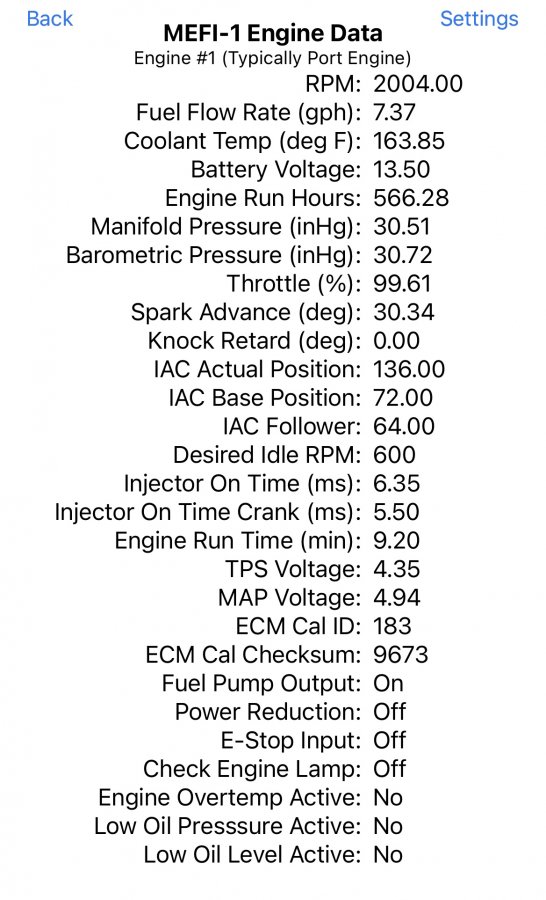

Assuming the Fox Marine gateway is accurate.....the ECM is reporting timing at 30.34 degrees, Injector On Time 6.35ms and a fuel flow rate at 7.37 gallons per hour (which is a calculated number).

Then when you consider that the Throttle is at 99.61% and Manifold/Barometric pressures are almost equal......something is stopping the fuel from flowing when the throttle is wide open and the spark has advanced. The OP reports that it smells lean not rich which is another clue that there isn't enough fuel being provided to match the air supply. (It would be helpful to see a picture of the current spark plugs.)

Now ask yourself: Given the data above......what circumstances exist for an ECM not to increase the Injector On Time?

The OP addressed:

-the exhaust issue

-fuel quality

-fuel pressure

-had the injectors tested and serviced

Revving in neutral to 4000 rpm only required 2.7ms of Injector On Time which is not a lot of fuel. So the question remains: "Why is the Injector On Time not increasing?"

This is what I am reacting to:

Tom, @ttmott

Assuming the Fox Marine gateway is accurate.....the ECM is reporting timing at 30.34 degrees, Injector On Time 6.35ms and a fuel flow rate at 7.37 gallons per hour (which is a calculated number).

Then when you consider that the Throttle is at 99.61% and Manifold/Barometric pressures are almost equal......something is stopping the fuel from flowing when the throttle is wide open and the spark has advanced. The OP reports that it smells lean not rich which is another clue that there isn't enough fuel being provided to match the air supply. (It would be helpful to see a picture of the current spark plugs.)

Now ask yourself: Given the data above......what circumstances exist for an ECM not to increase the Injector On Time?

The OP addressed:

-the exhaust issue

-fuel quality

-fuel pressure

-had the injectors tested and serviced

Revving in neutral to 4000 rpm only required 2.7ms of Injector On Time which is not a lot of fuel. So the question remains: "Why is the Injector On Time not increasing?"