Didn't he say that was done and several were shorted and not flowing then he bought new?I would start by pulling the injectors out and making sure they are all the same part number. If so, send them to an injector cleaning service. It’s $20-30 per injector and should be considered 10 yr maintenance anyway. The injectors “should” outlive the engines.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Absolutely frustrated with this Mercruiser engine

- Thread starter Hoplite808

- Start date

jmauld

Well-Known Member

- Jun 9, 2020

- 2,844

- Boat Info

- 2010 Sundancer 390

2016 Sea Hunt Ultra 211

- Engines

- Twin 8.1l of gas guzzling iron

I don’t know, I’m too lazy to read back through all of this mess.Didn't he say that was done and several were shorted and not flowing then he bought new?

Nater Potater

Well-Known Member

- Oct 19, 2020

- 2,646

- Boat Info

- 1992 300DA Sundancer

- Engines

- Twin Merc Alpha I Gen II I/O's with 5.7 V8's

Thank you for posting this. Mods, this should be a sticky if it's not already.Okay....even after having a couple of drinks....trying to sort out the OP wiring without actually seeing it leads me to think I'm wasting my time. This is the standard Mercruiser used to wire the engine harness:

Black Grounds, General

Black/Brown Pump Grounds

Black/Red Voltmeter Grounds

Black/Orange Isolated Accessory Grounds

Black/Yellow Ignition stop

Black/Green Water Level Sender Ground

Black/Blue Lighting Grounds

Black/Gray Nav Light Grounds

Black/White Battery Parallel Solenoid

Brown Pumps, General, Bilge or Sump (Manually Switched)(Also alternator starter to Ign.)

Brown/Red Pumps, Bilge or Sump

Brown/Orange Power feed to Auto Bilge Switches, Pumps, Fuel/Oil Tranfer or Priming

Brown/Yellow Baitwell or Aerator

Brown/Green Fresh Water Pump/Water Maker

Brown/Blue Head Pump

Brown/Violet Washdown Pump

Brown/White Trim pos sender

Red Battery Feeds Unprotected

Red/Violet Misc. Accy. Main Feed Protected (fused) from batt to trim panel.

Pink Fuel Sender

Orange/Black Audio System Feed

Orange/Brown Electric Head, Sanitation System

Orange/Red Wiper Port

Orange Accessories common feed, Dist Panel to Acc switch, Anode Electrode, Mercathode

Orange/Yellow Diesel Preheat

Orange/Green Wiper Stbd

Orange/Blue Communications Equipment

Orange/Violet Navigation Equipment

Orange/White Wiper Center

Yellow/Black Choke Neutral saftey trans mounted

Yellow/Red Start Solenoid (starting circut), Neutral Safety

Yellow/Orange Powered Ventilation, Fans

Yellow Bilge Blowers (also alternator DC output)

Yellow/White Rudder Angle Sender

Green/Red Stop Solenoid/Kill Switch

Green/Yellow AC Grounding

Green Bonding

Green/White Engine Trim in and or tilt down

Green/Orange Engine Independent Trim down

Blue/Black Cabin Lights

Blue/Brown Oil Temp Send

Blue/Red Cabin or Cockpit Lights Port

Blue/Orange Engine Independent Tilt Up

Blue/Yellow Lighting Circuits to Remote Send

Blue/Green Cabin or Cockpit Lights Stbd

Blue Instrument & General Lighting

Blue/Violet Courtesy, Boarding Lighting

Blue/White Engine Trim Outand/or Tilt Up

Light Blue Oil Pressure

Violet/Red Eng. or Generator B+ from Breaker

Violet/Yellow I/O Trim Up (ballast bypass)

Violet/Green I/O Trim Down

Violet 12v Ignition Generator or Engine

Violet/White Trim "Trailer" switch

Gray/Black Mast Light

Gray/Red Spotlight Remote

Gray/Orange Docking Lights

Gray/Green Strobe or Beacon

Gray/Blue Spreader/Flood Lights

Gray/Violet Windlass/Winch

Gray Navigation (running) Lights, Tach. Send

Gray/White Anchor Light

White/Brown Temp. Alarm or Indicator

White/Red Fuel Alarm or Indicator ((Ignition module to Dist.)Mercury Thunderbolt Ignition)

White/Orange Fire Alarm or Indicator

White/Yellow Air Flow Alarm or Indicator

White/Green Water Press/Flow Alarm or Indicator ((Ignition module to Dist.)Mercury Thunderbolt Ignition)

White/Blue Oil Press Alarm or Indicator

White/Violet Voltage Alarm or Indicator

White General Alarm Usage, Yamaha Kill Switch

Tan Water Temp sender

Tan/Blue Warning system sense wire (Audio warning)

As you can see the White with a Red stripe is used for a Fuel Alarm or Indicator on the Mercury Thunderbolt Ignition. IF the wire is original ......it doesn't show up on the EFI or Engine wiring harness diagrams for his engine.....but I have seen the wire before on Thunderbolt distributors.

In any case if the engine starts and runs.....even poorly....my money is still on the fuel system.

Speaking of money......the OP is quite clear that he doesn't want to spend $1,000+ on injectors just because CSR says it is the most reasonable solution.

I get it......I'm guessing he bought the boat for almost nothing after the original owner couldn't make it work and doesn't want to keep throwing money at it.

PlayDate

Well-Known Member

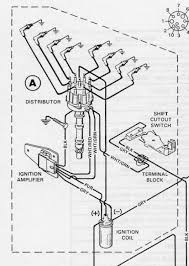

So .....the white/red wire matches the amplifier wire on a Thunderbolt IV distributor. On that distributor....the amplifier is external to the distributor so the sensing wires are: white/red and white/green.

Thunderbolt V had a few early versions with external amplifiers but later models integrated the amplifier with the distributor (your wiring diagram does not show this wire). Why it was spliced or repurposed is a mystery. It won't start if it is a IV without the amplifier. If it is a V that wire should be dead in the harness unless someone used it for another purpose.

Thunderbolt V had a few early versions with external amplifiers but later models integrated the amplifier with the distributor (your wiring diagram does not show this wire). Why it was spliced or repurposed is a mystery. It won't start if it is a IV without the amplifier. If it is a V that wire should be dead in the harness unless someone used it for another purpose.

Please, in a new thread called "Mercruiser EFI Tech" or something like that.....Thank you for posting this. Mods, this should be a sticky if it's not already.

Hmmm... interesting find, John... and great detective work!  That's not something I would have picked up on.

That's not something I would have picked up on.

If the engine is truly a '96 it should definitely be a Gen V or maybe even a Gen VI.

Possibly there's a previous retrofit going on here? Hop, can you post a pic of your distributor?

Can you verify if the engine EVER ran properly? Or was this a "project" when you bought it?

If the engine is truly a '96 it should definitely be a Gen V or maybe even a Gen VI.

Possibly there's a previous retrofit going on here? Hop, can you post a pic of your distributor?

Can you verify if the engine EVER ran properly? Or was this a "project" when you bought it?

PlayDate

Well-Known Member

Hmmm... interesting find, John... and great detective work!That's not something I would have picked up on.

If the engine is truly a '96 it should definitely be a Gen V or maybe even a Gen VI.

Possibly there's a previous retrofit going on here? Hop, can you post a pic of your distributor?

Can you verify if the engine EVER ran properly? Or was this a "project" when you bought it?

I believe he got the boat as a project and attacked the heads/manifolds first which makes sense but a look at the wiring photos indicates that we are dropping into this story many chapters after it started.

The engine number is right but I'm not sure about the rest. Nobody splices wires like that unless they are trying to do something and having trouble.

In regards to the white/red wire. I have that engine harness on my boat (Thunderbolt IV) so I just needed to see if they used it on the V (which they did on some very early versions). It comes with bullet connectors at the distributor that are male and female and can be installed only one way to the harness. A photo of the distributor and the nearby harness may give us a clue as to what they were trying to do. The OP should be able to locate the white/red and white/green wires in the harness next to the distributor with their bullet connector ends. If it is a V.....they won't be hooked up to the distributor.

Still my money is on the fuel system since it starts and runs. My concern is that something else with the fuel system could also be wrong.....bad fuel or fuel contamination.....toss in a new set of injectors and the problem doesn't change.

Before I bought the injectors I would definitely pull some fuel from the fuel rail and make sure it is okay. I don't recall the OP addressed the gas issue (the boat has not been working for years).....if there was old fuel in that tank......unless you drain and flush it.....new injectors won't matter.....the new fuel will be on top of the old fuel/condensation in the tank and will not mix to fix it.

scoflaw

Well-Known Member

- Aug 10, 2011

- 6,395

- Boat Info

- 1999 Powerquest legend 260 sx 502 mag

2005 Baja 242 islander 496

- Engines

- 502 mpi Bravo 1

496 mag B1

Post one says he flushed the gas tank and filled with new along with the laundry list of everything he replaced

PlayDate

Well-Known Member

Post one says he flushed the gas tank and filled with new along with the laundry list of everything he replaced

Yes....perhaps you can explain to us how he did it. For example did he drain it from the pickup tube. In that case how did he get all the old gas out? Did he do it from the filler .....again....how did he get all the old gas out? I'm curious and stopped taking people at their word a long time ago if they can't explain how they did it.

If the boat started with the old injectors and does not start with the new ones it must be the oil . Make sure you use 25w-40 quicksilver . Any other brand is a no start condition after replacing injectors .

Don,t believe it has something to do with fuel delivery . It must be the oil .

Don,t believe it has something to do with fuel delivery . It must be the oil .

Hoplite808

Well-Known Member

- Jan 11, 2022

- 507

- Boat Info

- 1996 Sea Ray 270 Sundancer

- Engines

- Mercruiser 7.4 LX MPI EFI (Gen. V)

Yes....perhaps you can explain to us how he did it. For example did he drain it from the pickup tube. In that case how did he get all the old gas out? Did he do it from the filler .....again....how did he get all the old gas out? I'm curious and stopped taking people at their word a long time ago if they can't explain how they did it.

I drained the gas by disconnecting the fuel line at the mechanical pump from the tank and attaching the hand vacuum pump I use for oil changes and spent the better part of a day pumping and pouring into red cans until the boats tank was empty. Put the fuel in my truck to dispose of it. Truck runs fine on it so fuel quality doesn’t seem to be an issue. The fuel I added a month or so ago was fresh from the station and non-ethanol. Fuel filter/water separator was then changed. Fuel pressure is holding at 37 psi at the rail even under load when it’s acting up. The new fuel injectors I got were from eBay and I paid $300 to have them and the old ones tested. Obviously the guy who tested them didn’t do it right. The SELOC manual said ohm test the injectors and if they are good they will show 12 ohms +/- .4. The old injectors all tested exactly at 12 and the new ones tested anything but. I tested both banks wiring with a test light and both banks appear to be functioning properly.

Hoplite808

Well-Known Member

- Jan 11, 2022

- 507

- Boat Info

- 1996 Sea Ray 270 Sundancer

- Engines

- Mercruiser 7.4 LX MPI EFI (Gen. V)

For those saying to get the $800 rinda tool all it would do is tell me what code the engine is throwing. The MEFI 1 computer in it from what I’ve read will offer very little diagnostic information beyond just the codes and I can already read for codes with my continuity tester. It is not currently throwing a code.

A little about fuel injectors -I drained the gas by disconnecting the fuel line at the mechanical pump from the tank and attaching the hand vacuum pump I use for oil changes and spent the better part of a day pumping and pouring into red cans until the boats tank was empty. Put the fuel in my truck to dispose of it. Truck runs fine on it so fuel quality doesn’t seem to be an issue. The fuel I added a month or so ago was fresh from the station and non-ethanol. Fuel filter/water separator was then changed. Fuel pressure is holding at 37 psi at the rail even under load when it’s acting up. The new fuel injectors I got were from eBay and I paid $300 to have them and the old ones tested. Obviously the guy who tested them didn’t do it right. The SELOC manual said ohm test the injectors and if they are good they will show 12 ohms +/- .4. The old injectors all tested exactly at 12 and the new ones tested anything but. I tested both banks wiring with a test light and both banks appear to be functioning properly.

- All the resistance measurement on a fuel injector validates is the coil that creates the magnetic field to open and close the pintel (valve) and allow fuel to spray into the intake tract. Nothing else.

- There are two types of coils - saturated and peak and hold.

- Yours are saturated (based upon what you state from the manual) which should be typically between 14 and 16 ohms. These are called "high impedance" injectors.

- Peak and hold injectors are typically between 0.4 and 6 ohms. These are called "low impedance" injectors.

- Installing a Peak and Hold injector with an ECM for Saturated injectors will damage the ECM.

- Because you get a proper resistance measurement on the coil doesn't mean the unit is opening and closing.

- Typically in marine applications that sit dormant, internal corrosion will lead to injectors not functioning properly or even functioning at all.

- There is a very fine screen filter at the inlet of the injector that will get gummed and varnished up from fuel that sits dormant for any length of time and will inhibit fuel delivery.

- The injector spray pattern is super critical to a properly running engine. An injector that dribbles fuel into the intake manifold will foul the cylinder.

You can take it or leave it from a fellow that buys dozens of injectors a year - you need to either get your existing injectors (if they are correct for the application) into a qualified injection shop for cleaning and rebuilding like RC Injection or get new - that is NEW Mercury injectors.

Overvolted

Active Member

- Feb 28, 2023

- 135

- Boat Info

- 1987 Sea Ray 268. Covered slip

- Engines

- 7.4 Mercruiser

Curious to the exhaust set up on this boat. I have had three engines in different vehicles, not boats mind you, exhibit the same symptoms: starts and runs, idle all day long and run well until put under heavy load at which point fall flat on their face and not build any more rpm's. All three had restrictions in the exhaust, no computer codes or any other issue except not having the ability to rev out.

techmitch

Well-Known Member

- May 1, 2008

- 8,396

- Boat Info

- 1999 270 DA

- Engines

- Twin 4.3s W/Alpa I Gen II's

God I want to figure this out and see what was wrong. It runs good to 2000 rpm then stops, something simple I hope

If the boat started with the old injectors and does not start with the new ones it must be the oil . Make sure you use 25w-40 quicksilver . Any other brand is a no start condition after replacing injectors .

Don,t believe it has something to do with fuel delivery . It must be the oil .

techmitch

Well-Known Member

- May 1, 2008

- 8,396

- Boat Info

- 1999 270 DA

- Engines

- Twin 4.3s W/Alpa I Gen II's

A little about fuel injectors -

- All the resistance measurement on a fuel injector validates is the coil that creates the magnetic field to open and close the pintel (valve) and allow fuel to spray into the intake tract. Nothing else.

- There are two types of coils - saturated and peak and hold.

- Yours are saturated (based upon what you state from the manual) which should be typically between 14 and 16 ohms. These are called "high impedance" injectors.

- Peak and hold injectors are typically between 0.4 and 6 ohms. These are called "low impedance" injectors.

- Installing a Peak and Hold injector with an ECM for Saturated injectors will damage the ECM.

- Because you get a proper resistance measurement on the coil doesn't mean the unit is opening and closing.

- Typically in marine applications that sit dormant, internal corrosion will lead to injectors not functioning properly or even functioning at all.

- There is a very fine screen filter at the inlet of the injector that will get gummed and varnished up from fuel that sits dormant for any length of time and will inhibit fuel delivery.

- The injector spray pattern is super critical to a properly running engine. An injector that dribbles fuel into the intake manifold will foul the cylinder.

"You can take it or leave it from a fellow that buys dozens of injectors a year - you need to either get your existing injectors (if they are correct for the application) into a qualified injection shop for cleaning and rebuilding like RC Injection or get new - that is NEW Mercury injectors.

Crazy thread, as are the other associated threads. That pic of the chocolate milk coated cylinder heads after the valve covers were removed was a sad sight to say the least.

May be the "Rocket man" has a suggested an extremely important check as the best first step moving forward.

You can take it or leave it from a fellow that buys dozens of injectors a year - you need to either get your existing injectors (if they are correct for the application) into a qualified injection shop for cleaning and rebuilding like RC Injection or get new - that is NEW Mercury injectors.[/QUOTE]

Hoplite808

Well-Known Member

- Jan 11, 2022

- 507

- Boat Info

- 1996 Sea Ray 270 Sundancer

- Engines

- Mercruiser 7.4 LX MPI EFI (Gen. V)

Curious to the exhaust set up on this boat. I have had three engines in different vehicles, not boats mind you, exhibit the same symptoms: starts and runs, idle all day long and run well until put under heavy load at which point fall flat on their face and not build any more rpm's. All three had restrictions in the exhaust, no computer codes or any other issue except not having the ability to rev out.

I replaced both exhaust manifolds and it is otherwise stock sterndrive setup. I also changed both flapper valves in the exhaust and the outdrive also was replaced entirely with a rebuilt one. There is no indication that I can tell that the current setup has any blockage.

Hoplite808

Well-Known Member

- Jan 11, 2022

- 507

- Boat Info

- 1996 Sea Ray 270 Sundancer

- Engines

- Mercruiser 7.4 LX MPI EFI (Gen. V)

[/QUOTE]Crazy thread, as are the other associated threads. That pic of the chocolate milk coated cylinder heads after the valve covers were removed was a sad sight to say the least.

May be the "Rocket man" has a suggested an extremely important check as the best first step moving forward.

You can take it or leave it from a fellow that buys dozens of injectors a year - you need to either get your existing injectors (if they are correct for the application) into a qualified injection shop for cleaning and rebuilding like RC Injection or get new - that is NEW Mercury injectors.

I replied before that the miniscule amount of oil with water you saw in that photo was due to some residual water spilling out of the exhaust manifold as I removed it. There was no water mixed with the oil inside the engine. Everything else that was brown there was a bit of surface rust which should be expected on a 23 year old marine engine. Lastly, that photo was taken before I removed the head and had it redone at a machine shop.

Bill Curtis

Well-Known Member

- Mar 24, 2022

- 1,014

- Boat Info

- '95 220 Overnighter

454 Mag. Bravo3 w/ 2.0:1 gears and 28 pitch props

- Engines

- 454 Mag Bravo3. 2.0:1 ratio gears w/ 28 pitch props

I replaced both exhaust manifolds and it is otherwise stock sterndrive setup. I also changed both flapper valves in the exhaust and the outdrive also was replaced entirely with a rebuilt one. There is no indication that I can tell that the current setup has any blockage.

One thing that CAN happen in the exhaust that isn't readily visible, is there could possibly be an old flapper that fell apart (usually from an overheat or from a while ago) and fell into the exhaust "Y". They can be in there a long time before being noticed. This I have seen more than once on other boats. An old flapper down there can / will block the exhaust and cause problems, including possibly eating a hole through the aluminum "Y" pipe and causing a water leak. Easy to check, Take off the riser and the pipe elbow after it and look down there with a cheap borescope.