Irie308

Well-Known Member

- May 28, 2013

- 2,599

- Boat Info

- 2004 420 DB, GHS Hydraulic Lift

Garmin 8600/Garmin 1222 plus

AB Mares 10 VSX with 30 hp Tohatsu

- Engines

- Cummins 450C 8.3 L Turbocharged

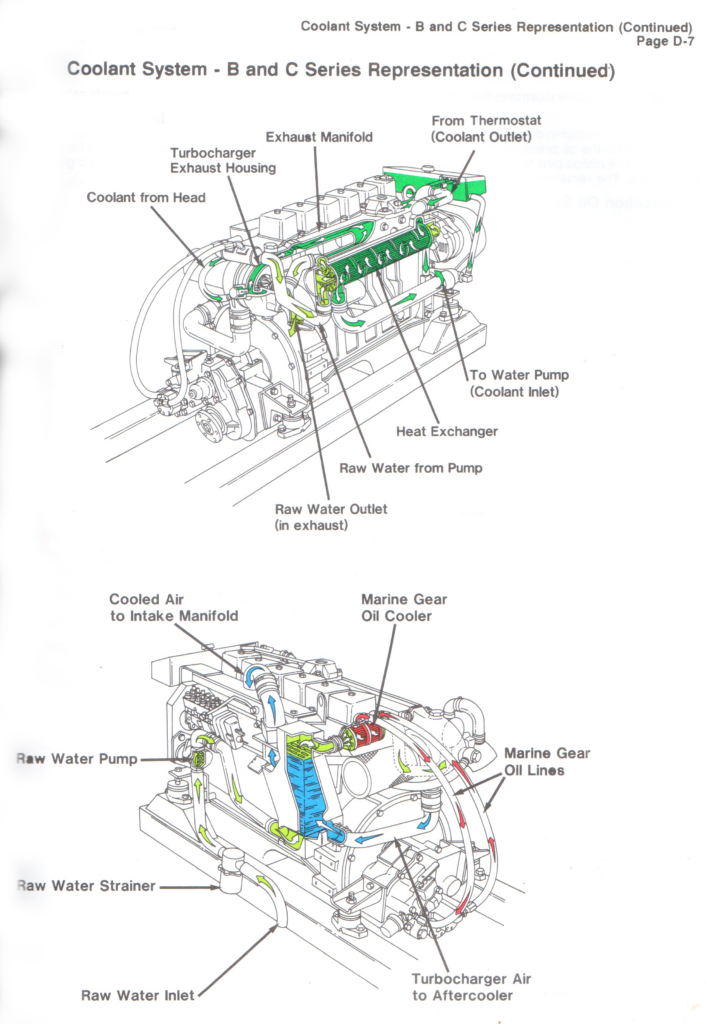

Post #1456 was underway and yes the readings were in the 150's. My earlier post #1446 was at the dock. I did test the sensors in hot water prior to installing so I do think they are very accurate. However I've been trying to understand this flow chart from the seaboard site as I agree that the manifold coolant should be the hottest as it seems to be the last stop before the tstats. What I did observe is that it would get to 158 then it would drop down to 152. My assumption is that while running the tstats are mostly "somewhat" open because of the time it takes them to open and close. I think, and correct me if I'm wrong, the analog temp sensor is down in the area below the tstat housing near the alternator which seems to have the hotter coolant.OK, I must have misread your posts and photos. I thought the temps in the 150’s were underway and from the sensor you put in the exhaust manifold. The exhaust manifold is the hottest coolant, it goes from there to the tstats. 150‘s wouldn’t even open them to send the coolant to the hx