370Dancer

Well-Known Member

- Oct 2, 2006

- 2,489

- Boat Info

- 1998 370 Sundancer

- Engines

- 380hp MAG MPI Gen VI with V drives

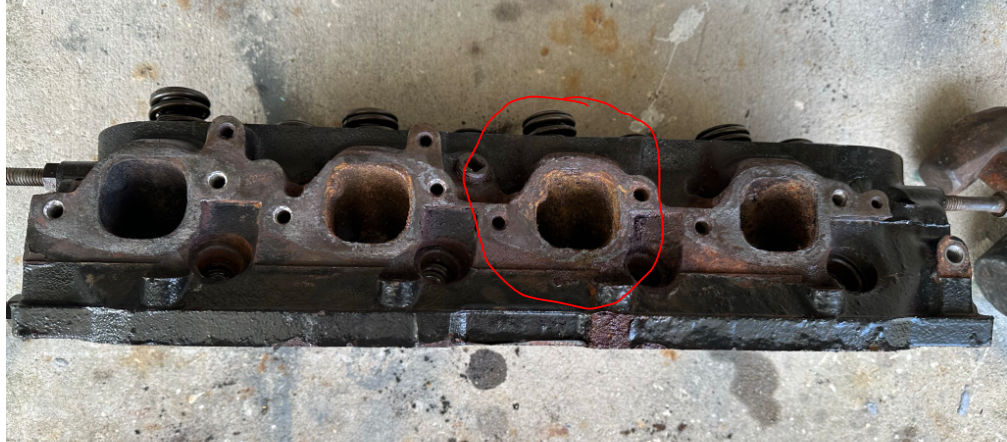

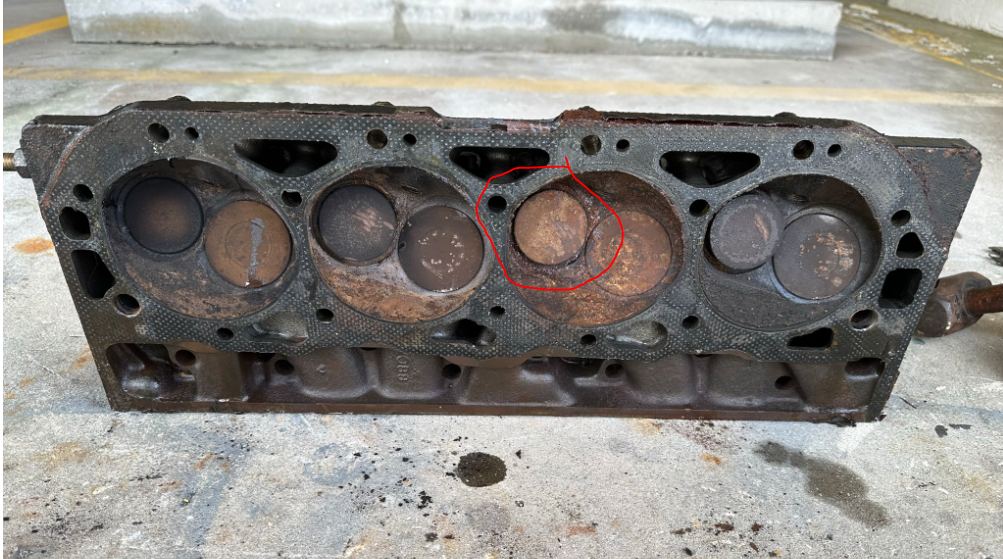

Heads off, and waiting for OE new replacements. A bit distraught. No breaks in any gasket or anything obvious for why exhaust water got into #5, except through reversion, or perhaps a bad exhaust manifold/riser/extension/gaskets. They are new, with about 2 hours on them. The valve was rusted halfway open, so it didn't hit the piston. I'm inclined to add a 12" extension of the exhaust at the elbow to move the mix downstream towards the waterlift. 2" od SS tubing is too small. Anyone have a spec on the id of the exhaust on the elbow? 3" perhaps?